Product Description

Excellent Quality of Our Sintered Powder Metallurgy parts

Our company is producing and exporting wide variety of automotive parts, textile machine, sewing machine, gasoline generator, power tools, oil pump rotor, clutch, oilless bearing, bushings, clutch and so many others with high quality. We can support various powder metallurgy parts including iron, copper, stainless steel and alloy materials based with high quality and reasonable prices. We can also make different sizes and models as the customers’ desired orders.

Over 200 workers are supporting and producing under the control of 3 Professional Engineers who has 20 years experiences in this production. We are always receiving customers’ feedbacks and changing the supplier products as the needs of our customers by special service team.

If you are interested in our products, please do not hesitate to contact us.

Our Products Special Features,

1) Our products passed TS16949 ISO-9001: 2000 quality management system verification

2) Material: Steel, copper, brass, aluminum, Titanium

3) Equipment: CNC lathe, CNC milling machine, CNC high-speed engraving machine, Common machines, laser engraving machines, metal injection machine

4) Precision machining capability:

5) Advanced workmanship, fitting tool, fixture, cutting tool

6) Parts can be supplied according to customers’ drawings or samples.

7) 2D/3D drawings or samples are welcome!

8). Best quality, competitive price, shortest delivery time and good service.

| Place of origin: | ZHangZhoug, China |

| Brand Name: | HangZhou Xihu (West Lake) Dis. Powder Metallurgy Co.,Ltd |

| Type: | Powder metallurgy sintering |

| Surface finish | e-coating, electroplating and black oxygen |

| Measuring method | 3D system, High-lubrication, high-density and high-strength |

| Inspection equipment | Torsion test, voltage feedback test, HRC density test, lifting test and salt spray resistant test and more |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron, stainless steel, copper, Alloy |

| Application: | Automotive parts, power tools, stainless steel, bushings, clutches and so many others |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgy, CNC Machining |

| Powder Metallurgy: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

Powder Metallurgy Component Production Process

A trained, qualified, and dedicated work force

1) Engineering is our strength – we will help your designers convert your parts to cost-effective powdered metal parts.

2) Every employee is trained to a standard of excellence.

Quality is designed into the process

1) Consistent and committed attitude to quality first.

Critical characteristics are measured and controlled using the latest statistical methods

1) Quality is always the first priority.

2) Our subcontractors are held to the same high standards.

OUR FACTORY

Certification

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

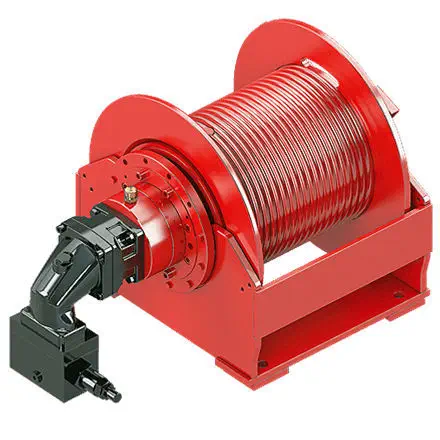

| Type: | Electric Winch |

|---|---|

| Power Type: | Permanent-magnet DC |

| Pull Direction: | Forward |

| Manual Winch Type: | Sintered Metal |

| Electric Winch Model: | ATV |

| Working Voltage of Electric Winch: | High Voltage |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

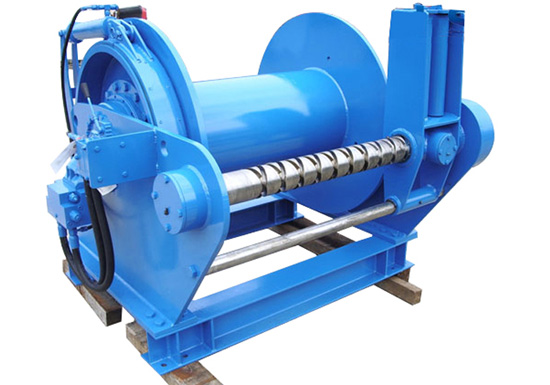

Are there innovations or advancements in hydraulic winch technology that have emerged recently?

Yes, there have been notable innovations and advancements in hydraulic winch technology in recent years. These developments aim to enhance performance, safety, and efficiency in various industries. Some of the key advancements include:

- 1. Electronic Control Systems: Modern hydraulic winches often come equipped with advanced electronic control systems. These systems offer features like load sensing, variable speed control, and remote operation, allowing for precise and convenient winching operations.

- 2. Energy Efficiency: Manufacturers have focused on improving the energy efficiency of hydraulic winches. This includes the use of more efficient hydraulic pumps and components, which can reduce fuel consumption in applications like tow trucks and construction equipment.

- 3. Compact Designs: Advancements in hydraulic system design have resulted in more compact winches that can fit into tighter spaces. This is particularly beneficial in industries where space is limited or where winches need to be integrated into existing equipment.

- 4. Enhanced Safety Features: Recent hydraulic winches often incorporate additional safety features, such as load monitoring, emergency stop systems, and automatic overload protection. These features help prevent accidents and protect equipment.

- 5. Telematics and Data Logging: Some hydraulic winches now feature telematics and data logging capabilities. This allows operators to monitor winch performance, track usage, and perform remote diagnostics, improving maintenance and efficiency.

- 6. Improved Sealing and Corrosion Resistance: Advances in materials and sealing technology have made hydraulic winches more resistant to environmental factors. They can better withstand harsh weather conditions and corrosive environments, extending their lifespan.

- 7. Integration with Vehicle Systems: In industries like towing, hydraulic winches are increasingly integrated with the vehicle’s overall control systems. This integration allows for seamless operation and improved safety features.

- 8. Enhanced Load Control: Innovative hydraulic winches offer improved load control features, including load holding, inching, and precise positioning. These capabilities are particularly valuable in construction and material handling applications.

These recent innovations in hydraulic winch technology aim to address the evolving needs of industries such as construction, towing, and material handling. They contribute to safer, more efficient, and more reliable winching operations.

What maintenance practices are recommended for hydraulic winches to ensure optimal functionality?

Proper maintenance of hydraulic winches is essential to ensure their optimal functionality, extend their service life, and enhance safety. Here are recommended maintenance practices for hydraulic winches:

- 1. Regular Inspection: Conduct routine visual inspections of the winch, including all components, hoses, and fittings. Look for signs of wear, leaks, corrosion, or damage. Inspect the winch drum, cable, and control mechanisms for any issues.

- 2. Lubrication: Ensure that all moving parts are adequately lubricated. Pay special attention to bearings, gears, and pivot points. Lubrication reduces friction, minimizes wear, and ensures smooth operation. Use the recommended lubricants specified by the manufacturer.

- 3. Hydraulic Fluid Checks: Monitor the hydraulic fluid level and condition regularly. Check for leaks in the hydraulic lines and fittings. Maintain the proper hydraulic fluid level and replace or top up fluid as needed with the correct type recommended by the manufacturer.

- 4. Control System Inspection: Examine the winch’s control system, including buttons, switches, and joysticks. Ensure that they function correctly and respond to commands promptly. Clean control surfaces to prevent dirt or debris from interfering with operation.

- 5. Cable Inspection: Inspect the winch cable or rope for signs of wear, fraying, or damage. Replace cables that show wear or damage to prevent accidents during operation. Ensure proper winding on the drum to avoid cable overlap or uneven spooling.

- 6. Brake System Check: If the winch is equipped with a brake system, verify that it engages and disengages properly. The brake system is critical for load control and safety during winching operations.

- 7. Fastener Tightening: Periodically check and tighten all fasteners, bolts, nuts, and hose clamps. Loose fasteners can lead to component failure or hydraulic fluid leaks.

- 8. Filter Maintenance: If the winch has hydraulic filters, follow the manufacturer’s guidelines for filter replacement or cleaning. Clean or replace filters regularly to prevent contamination of the hydraulic system.

- 9. Seal Inspection: Examine hydraulic seals for signs of wear or leaks. Damaged seals can lead to hydraulic fluid leaks and reduced winch performance. Replace seals as needed.

- 10. Electrical System Inspection: If the winch has electrical components, inspect wiring, connectors, and electrical connections for damage or corrosion. Ensure that the electrical system is in good working condition.

- 11. Operator Training: Ensure that operators are properly trained in the use of hydraulic winches. Adequate training can prevent misuse and accidents that may lead to equipment damage or injuries.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their winches, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Professional Service: Consider having the winch professionally inspected and serviced periodically. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, hydraulic winches can operate optimally, promoting safety, reliability, and longevity in various industries and applications.

In what scenarios are hydraulic winches commonly used, and what advantages do they offer?

Hydraulic winches find common use in various scenarios across different industries, thanks to the advantages they offer. Here are scenarios where hydraulic winches are commonly employed and their associated benefits:

- 1. Off-Road and Recovery: Hydraulic winches are extensively used in off-road vehicles, including trucks, jeeps, and ATV/UTVs, for self-recovery and assisting stuck vehicles in challenging terrains. Advantages include their high pulling power and durability in rugged conditions.

- 2. Construction and Material Handling: In construction and material handling, hydraulic winches are employed for lifting heavy materials, positioning equipment, and pulling loads. They offer precise control, high load capacity, and continuous operation, making them indispensable for construction tasks.

- 3. Marine and Maritime: Hydraulic winches play a crucial role in maritime industries for anchor handling, mooring operations, and cargo handling on ships and offshore platforms. They offer resistance to saltwater corrosion and ensure safe vessel operations.

- 4. Oil and Gas: The oil and gas sector relies on hydraulic winches for lifting heavy equipment, handling drilling tools, and controlling rig components during drilling and well servicing operations. They provide strength and reliability in demanding environments.

- 5. Forestry and Logging: In forestry, hydraulic winches are used for skidding and hauling logs. Their robustness and load capacity make them ideal for moving heavy timber through challenging terrain, enhancing efficiency in logging operations.

- 6. Agriculture: Agricultural machinery, such as tractors and combines, may employ hydraulic winches for various applications, including lifting and lowering implements and adjusting equipment height. They contribute to agricultural productivity and versatility.

- 7. Mining: The mining industry uses hydraulic winches for hauling ore, positioning heavy machinery, and handling materials underground. Their ability to withstand harsh mining conditions and handle substantial loads is critical for mining operations.

- 8. Industrial Manufacturing: Manufacturing facilities utilize hydraulic winches for material handling, machinery positioning, and assembly line operations. They offer precise control over movement, improving manufacturing efficiency.

- 9. Utilities and Power Generation: Utilities and power generation companies employ hydraulic winches for tasks like installing utility poles, positioning power line components, and equipment maintenance. They ensure safe and reliable infrastructure operations.

- 10. Emergency Services: Hydraulic winches are vital for fire departments and emergency response teams for vehicle extrication and rescue operations. They assist in freeing trapped individuals and recovering vehicles in emergency situations.

Advantages of hydraulic winches in these scenarios include their exceptional load capacity, precise control, durability, resistance to harsh environments, continuous operation capability, and adaptability to a wide range of tasks. These qualities make hydraulic winches a preferred choice for industries that require heavy-duty and reliable winching solutions.

editor by Dream 2024-05-17