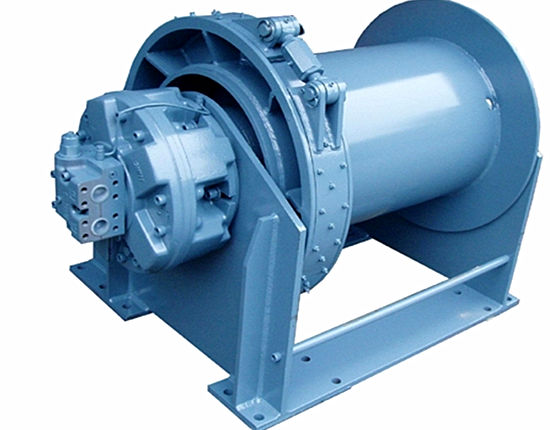

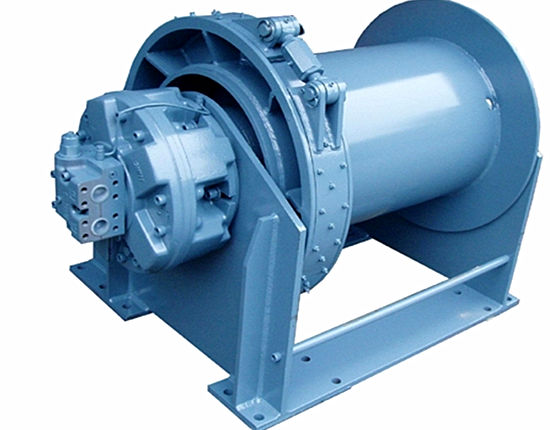

Product Description

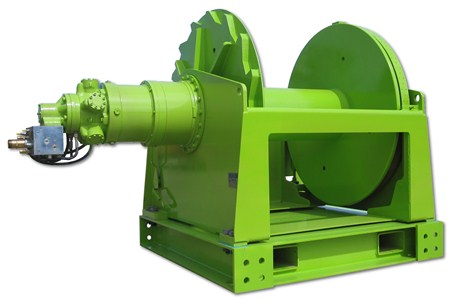

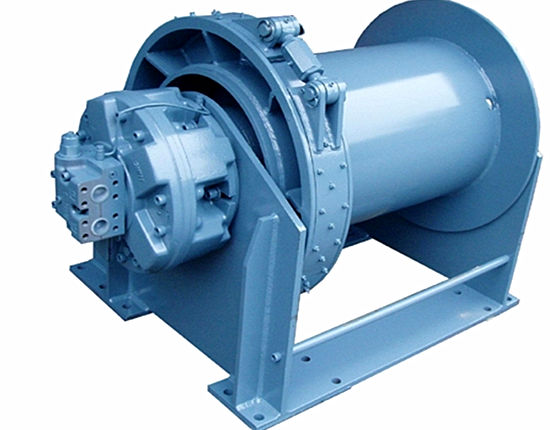

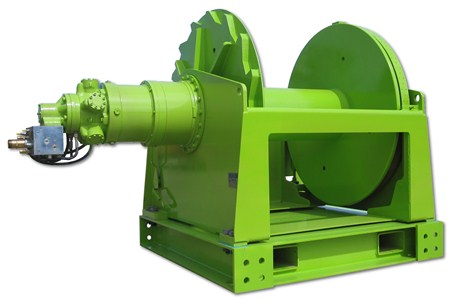

Planetary winch gearboxes of the HFW series are composed of 18 finely spaced frame sizes. The compact design allows the gearbox to be integrated into the winch drum. The failsafe brake can be integrated inside the gearbox or mounted externally, with common lubrication for the gears. Electrically driven versions are available with both in-line and right-angle configurations. Torque ratings are organized by FEM class, in accordance with minimum approved class safety factors for gears.

Features:

Compact structure and space-saving design

Robust main bearing system

High torque capacity

High load capacity

Integrated static multiple disk parking brake

Optional Disconnect device for towing

Optional Quick disconnection device

Simple mounting

Easy oil change

Low-noise running operation

Class approval program

ATEX conformity on demand

Torque ratings are organized by FEM class

The failsafe brake can be integrated inside the gearbox or mounted externally, with common lubrication for the gears

Specifications:

| 1 | Materials |

All torque-bearing gearbox components are made of top-quality casehardened and tempered steels. |

| 2 | Gearbox structure |

All sun gears and planet wheels are case-hardened and ground. The ring gears are made of high-strength tempered steel, which is also used for the forged planetary supports. Well thought-out construction principles ensure an even load distribution of the individual stages and therefore a high performance density. In addition, the gearboxes are characterised by an integral design optimised to reduce the number of components to a minimum, thereby also minimising the number of sealing points. |

| 3 | Bearings |

All rotation parts run on rotation element bearings .Ball bearings are used to support the input gearing,cylindrical Roller Bearings for the planet wheels and tapered Roller Bearings are used on the output gearing . |

| 4 | Seals |

Travel drives and winch drives use floating oil seals, slewing drives use rotating glyd ring seals. |

In conclusion, ELITE Hydraulic offers quality, value, and professional power transmission solutions that cater to a wide variety of industries. With their expertise, experience, and commitment to customer satisfaction, you can be sure that you’re in safe hands when working with them. Whether you need travel gearbox, electrical drive, travel drive,slew gearbox,winche gearbox,cutter gearbox,truck mixer gearbox,twin shaft mixer or other hydraulic transmission solutions, you can trust ELITE Hydraulic to provide you with the best possible solutions. Contact them today to learn more about their power transmission products and services.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24h |

|---|---|

| Warranty: | 18months |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | Fast |

| Carrying Capacity: | Middle-Level |

| Customization: |

Available

|

|

|---|

How does the choice of hydraulic winches affect the overall performance and reliability of winching systems?

The selection of hydraulic winches has a significant impact on the overall performance and reliability of winching systems. The following factors highlight how this choice influences winching operations:

- 1. Load Capacity: Different hydraulic winches come with varying load capacities. Choosing a winch with an appropriate load capacity for the intended application is crucial. An inadequately rated winch may lead to overloading, reducing both performance and reliability.

- 2. Line Speed: Hydraulic winches offer variable line speed control. Selecting a winch with the right line speed range ensures that you can match the winching speed to the specific task. This contributes to performance and safety.

- 3. Durability and Construction: The quality of materials and construction affects the winch’s longevity and reliability. High-quality materials and robust build reduce the risk of breakdowns and failures, especially in demanding applications.

- 4. Safety Features: The presence of safety features, such as overload protection and emergency stop mechanisms, is crucial for reliability and operator safety. Choose a winch with comprehensive safety features to minimize accidents and equipment damage.

- 5. Environmental Adaptability: Consider the environmental conditions in which the winch will operate. Hydraulic winches can be equipped with features like special seals or temperature control mechanisms to adapt to extreme temperatures or corrosive environments, enhancing overall reliability.

- 6. Control Systems: Modern hydraulic winches often include electronic control systems. These systems offer advanced control features and enhance precision, contributing to overall performance. Choosing a winch with advanced controls can improve efficiency.

- 7. Mounting and Integration: Proper mounting and integration of the winch into the equipment or vehicle are essential for reliability. A well-mounted winch is less likely to suffer from structural issues or misalignment during operation.

- 8. Maintenance Requirements: The ease of maintenance and availability of replacement parts can affect the long-term reliability of the winching system. Choose a winch with accessible components and a manufacturer that provides support.

- 9. Load Control Features: Hydraulic winches offer load control features like load-holding and inching. These features contribute to precise load handling and control, enhancing reliability in tasks that require careful positioning.

- 10. Compatibility: Ensure that the chosen hydraulic winch is compatible with the equipment or vehicle it will be used with. Compatibility issues can lead to operational problems and reduced reliability.

In summary, the choice of hydraulic winches significantly influences the overall performance and reliability of winching systems. It affects load handling capabilities, safety, durability, and adaptability to different conditions. Therefore, selecting the right hydraulic winch for the specific application is critical to ensuring a reliable and efficient winching operation.

How do hydraulic winches compare to electric or manual winches in terms of performance?

Hydraulic winches, electric winches, and manual winches each offer distinct performance characteristics, and their suitability depends on the specific application. Here’s a comparison of hydraulic winches with electric and manual winches in terms of performance:

- 1. Load Capacity: Hydraulic winches typically outperform electric and manual winches in terms of load capacity. They can handle much heavier loads due to the hydraulic system’s ability to generate high force.

- 2. Line Speed: Electric winches tend to have faster line speeds compared to hydraulic winches, making them suitable for tasks that require quick retrieval or lifting. Hydraulic winches offer more precise control but may have slightly slower line speeds.

- 3. Precision and Control: Hydraulic winches offer precise control over load movement, making them suitable for applications that require accurate positioning or controlled lifting. Electric winches also provide good control, while manual winches may be less precise.

- 4. Continuous Operation: Hydraulic winches are well-suited for continuous operation without overheating. Electric winches can operate continuously, but some may require intermittent use to prevent overheating. Manual winches are generally used for intermittent or occasional tasks.

- 5. Versatility: Hydraulic winches are versatile and can handle a wide range of applications and load sizes. Electric winches are also versatile but may have limitations on load capacity and duty cycle. Manual winches are less versatile and typically used for lighter loads and simpler tasks.

- 6. Maintenance: Hydraulic winches may require more maintenance due to their hydraulic system, including fluid changes and hydraulic component checks. Electric winches have fewer maintenance requirements, while manual winches are relatively low maintenance.

- 7. Power Source: Hydraulic winches require a hydraulic power source, which can be an advantage or limitation depending on the availability of hydraulic systems in the application. Electric winches need electrical power, while manual winches rely on human effort.

- 8. Environmental Considerations: Hydraulic winches are suitable for a wide range of environments, including harsh conditions, but require hydraulic fluid. Electric winches may be limited by electrical connections, and manual winches are suitable for less demanding environments.

- 9. Cost: Hydraulic winches are often more expensive upfront due to their hydraulic system. Electric winches come in various price ranges depending on capacity and features, while manual winches are generally the most affordable option.

Ultimately, the choice between hydraulic, electric, or manual winches depends on the specific requirements of the application. Hydraulic winches excel in heavy-duty applications where high load capacity and precise control are essential. Electric winches offer a balance between versatility and speed, while manual winches are suitable for lighter tasks and situations where a power source is not available.

Can you describe the factors to consider when selecting hydraulic winches for specific applications?

Selecting the right hydraulic winch for a specific application involves considering various factors to ensure optimal performance and safety. Here are key factors to take into account:

- 1. Load Capacity: Determine the maximum load the winch will need to handle. Choose a hydraulic winch with a capacity that comfortably exceeds the heaviest load you anticipate. Keep in mind that it’s safer to have a winch with a higher capacity than required.

- 2. Line Speed: Consider the speed at which you need to pull or lift the load. Hydraulic winches offer different line speeds, so choose one that aligns with your application’s requirements. Keep in mind that line speed may vary depending on the load.

- 3. Duty Cycle: Evaluate how frequently and for how long the winch will be in operation. Some winches are designed for continuous use, while others have intermittent duty cycles. Ensure the winch’s duty cycle matches the demands of your application.

- 4. Mounting and Installation: Assess the available space for mounting the winch and the compatibility of the winch’s mounting configuration with your equipment or vehicle. Consider the ease of installation and any additional mounting accessories required.

- 5. Control Options: Determine the level of control you need over the winch. Hydraulic winches may offer manual, remote, or integrated control options. Choose a control method that suits your operational preferences and safety requirements.

- 6. Environmental Conditions: Consider the environmental conditions in which the winch will operate. Hydraulic winches are suitable for various environments, but factors like temperature extremes, exposure to saltwater, and dust levels may influence your choice.

- 7. Safety Features: Check for safety features such as overload protection, emergency stop mechanisms, and fail-safe braking systems. These features enhance operator safety and protect against accidents.

- 8. Cable or Rope Type: Select the appropriate type of cable or rope for your application, considering factors like strength, durability, and compatibility with the winch drum. Ensure that the winch drum can accommodate the chosen cable or rope size.

- 9. Maintenance Requirements: Evaluate the maintenance needs of the hydraulic winch. Some models may require more frequent maintenance than others. Choose a winch that aligns with your maintenance schedule and capabilities.

- 10. Budget Considerations: Set a budget for the hydraulic winch purchase. While it’s essential to meet your application’s requirements, also consider the cost of the winch, installation, and any additional accessories or hydraulic system modifications.

- 11. Brand Reputation and Support: Research and select reputable brands with a history of manufacturing reliable hydraulic winches. Consider the availability of spare parts, technical support, and warranty coverage from the manufacturer.

- 12. Compliance with Standards: Ensure that the selected hydraulic winch complies with relevant industry standards and regulations. This is particularly important in safety-critical applications.

By carefully considering these factors, you can choose the right hydraulic winch that meets the specific requirements of your application, ensuring safe and efficient winching operations.

editor by Dream 2024-05-17

China factory Hydraulic Winch with High Speed 17 Tons Customized 17000 Kgs / 35000 Lbs

Product Description

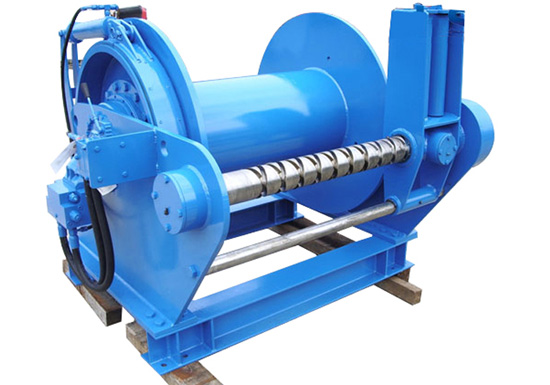

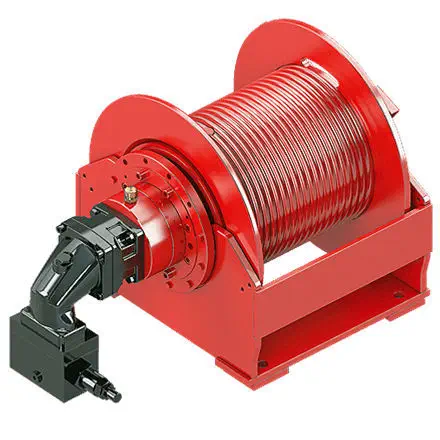

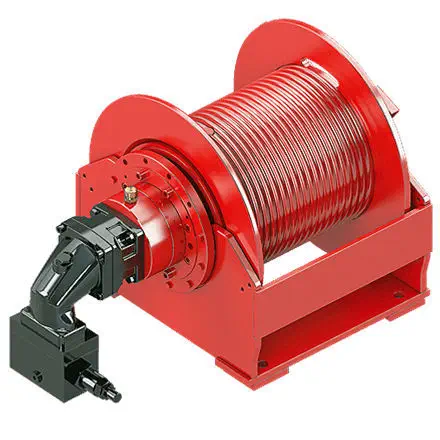

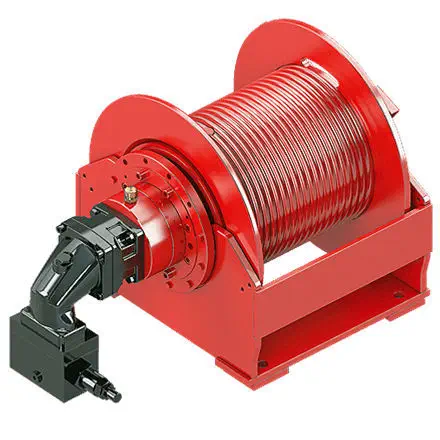

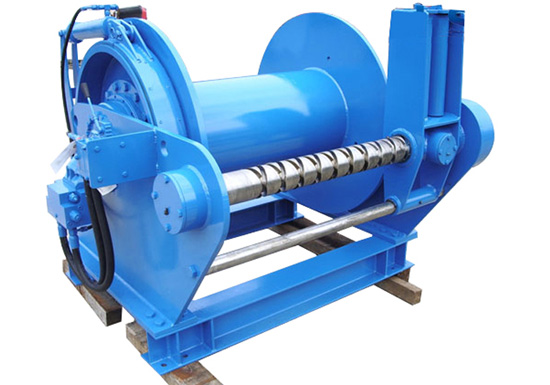

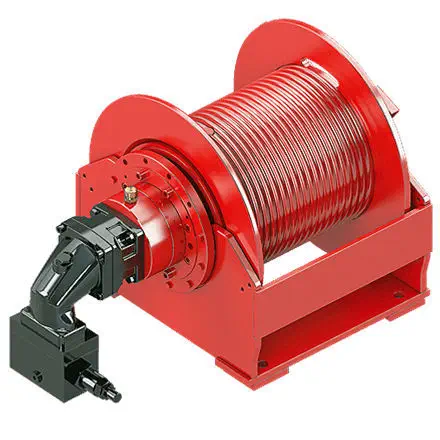

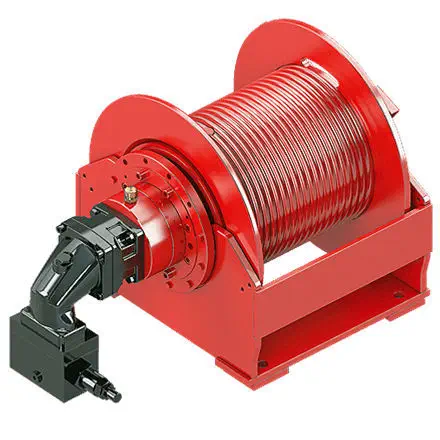

Hydraulic Winch with High Speed 17 tons customized 17000 KGS / 35000 lbs

Hydraulic Winch with High Speed 17 tons customized 17000 KGS / 35000 lbs is especially designed for heavy-duty lifting, pulling and towing operations. It is a good choice when an electric winch machine cannot match your operating and performance conditions. Powered by a hydraulic system, this type of winch has more strength than an electric power winch, thus it is ideal for the most demanding tasks in construction, mining and marine. Our winches can be designed and built into any size and form to meet your application demands.

2. YJP150 hydraulic winch consists of hydraulic motor, 2-stage planetary gear reducer, arrester, drum, etc.

a. High efficiently hydraulic motor(brand motor) .

b. Full-float typed planetary gear reducer

c. Multi-disc friction closed brake

d. Small size

e . Free spooling function.

| Performance | ||

| Rated line pull (1st layer) | Kn/Kgs / lbs | 147/ 17000 / 35000 |

| Line speed (1st layer) | m/min | 6 |

| Response pressure of brake | MPa / Bar | 2.5 / 25 |

| Oil pressure | MPa / Bar | 16 / 160 |

| Oil flow | L/min | 110 |

| Drum diameter x Bottom diameter x Length(internal) | mm | 400x210x340 |

| Drum capacity | m | 55 |

| Suggested high-intensity wire rope diameter | mm | Φ22 |

| Net weight | Kg | 285 |

COMPANY PROFILE

FAQ

1. Who are we?

We are based in ZheJiang , China, start from 1998. We are factory that producing hydraulic winch for more than 23 years.

2. What is your terms of payment?

A: T/T 30% in advanced,70% see the B/L copy . B.100% Irrevocable LC

3.What is your terms of delivery?

A. FOB, CFR ,CIF or as your requirement.

4. How about your delivery time?

A: Generally, it will take 3 to 25 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 1 Year |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | as Customer Requirement |

| Carrying Capacity: | Middle-Level |

| Samples: |

US$ 1500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety considerations should be taken into account when using hydraulic winches in various settings?

Using hydraulic winches in different settings requires careful attention to safety measures to prevent accidents and ensure the well-being of operators and others nearby. Here are important safety considerations:

- 1. Operator Training: Ensure that operators are properly trained in the operation of hydraulic winches. Training should cover the safe use of controls, emergency procedures, and an understanding of the winch’s load capacity and limitations.

- 2. Equipment Inspection: Conduct pre-use inspections to check the winch and associated equipment for signs of wear, damage, or malfunction. Look for issues with cables, hydraulic lines, controls, and safety mechanisms.

- 3. Load Rating: Always respect the winch’s load rating and capacity. Avoid overloading the winch, as this can lead to equipment failure and accidents. Refer to the winch’s documentation for load limits.

- 4. Secure Mounting: Ensure that the winch is securely and properly mounted to the equipment or vehicle. Loose or improper mounting can lead to accidents and equipment damage during operation.

- 5. Cable Inspection: Regularly inspect the winch cable for signs of wear, fraying, or damage. Replace damaged cables promptly to prevent accidents caused by cable failure.

- 6. Controlled Operation: Operate the winch smoothly and with control. Avoid abrupt starts and stops that can cause shock loading and endanger safety. Use variable line speed settings for precision.

- 7. Load Control: Use appropriate load control techniques, such as load-holding or inching, to ensure that loads are lifted, pulled, or lowered in a controlled manner. Prevent sudden and unexpected movements.

- 8. Remote Control: Whenever possible, operate the hydraulic winch from a safe distance using remote controls. This minimizes the risk to operators in case of unexpected load movement.

- 9. Emergency Stop: Familiarize operators with the emergency stop procedures and mechanisms of the hydraulic winch. Ensure that they know how to quickly stop the winch in case of emergencies or malfunctions.

- 10. Regular Maintenance: Follow a routine maintenance schedule recommended by the manufacturer. Regular maintenance checks for leaks, worn components, and overall winch condition. Address any issues promptly.

- 11. Hydraulic Fluid: Monitor hydraulic fluid levels and quality. Keep hydraulic fluid clean and at the recommended level to ensure proper winch operation. Address hydraulic leaks promptly to prevent fluid contamination.

- 12. Environmental Considerations: Be aware of the environmental conditions in which the winch is used. Extreme temperatures, moisture, and corrosive environments can affect the winch’s performance and safety. Consider environmental factors in maintenance and operation.

- 13. Communication: Establish clear communication protocols among team members involved in winching operations. This ensures that everyone is aware of the plan, roles, and safety procedures.

- 14. Regulatory Compliance: Be aware of and comply with safety regulations and standards specific to your industry and location. Compliance helps ensure safe winch operation and prevents regulatory issues.

Adhering to these safety considerations when using hydraulic winches is essential to prevent accidents, protect personnel, and maintain the integrity of equipment. Safety should always be a top priority in winching operations.

How does the hydraulic system impact the overall efficiency and reliability of winching operations?

The hydraulic system plays a significant role in enhancing the efficiency and reliability of winching operations. Its impact is substantial, making hydraulic winches preferred choices in various applications. Here’s how the hydraulic system contributes to overall efficiency and reliability:

- 1. High Force Output: Hydraulic winches can generate high force, thanks to the hydraulic fluid’s incompressible nature. This high force allows them to handle heavy loads efficiently and overcome resistance, making them reliable for challenging tasks.

- 2. Precise Control: Hydraulic systems provide precise control over winching operations. Operators can finely adjust the speed and direction of movement, allowing for accurate positioning and controlled lifting or pulling. This precision minimizes the risk of accidents and damage to equipment or loads.

- 3. Consistent Performance: Hydraulic systems offer consistent performance, regardless of load variations. The hydraulic pump maintains a constant flow of fluid, ensuring that the winch operates at a consistent speed and force. This consistency is crucial for reliable and predictable operations.

- 4. Variable Line Speed: Hydraulic winches offer variable line speed control. By adjusting the flow rate of hydraulic fluid, operators can vary the winch’s speed to match specific requirements. This adaptability improves efficiency in tasks with varying speed demands.

- 5. Overload Protection: Many hydraulic winches are equipped with overload protection mechanisms. These safety features prevent the winch from exerting excessive force beyond its capacity, reducing the risk of equipment damage or failure. Overload protection enhances the reliability of winching operations.

- 6. Durability and Longevity: Hydraulic systems are known for their durability and longevity. They can withstand heavy use and harsh environmental conditions. Properly maintained hydraulic winches can have a long service life, reducing downtime and replacement costs.

- 7. Low Heat Buildup: Hydraulic systems produce less heat during operation compared to electric winches. Lower heat buildup reduces the risk of overheating and extends the life of hydraulic components, contributing to reliability.

- 8. Adaptability to Environmental Conditions: Hydraulic winches can be adapted to various environmental conditions. Special seals, coolers, or heaters can be added to ensure proper hydraulic fluid temperature regulation, making them reliable in extreme temperatures or corrosive environments.

- 9. Reduced Shock Loading: The smooth and controlled operation of hydraulic winches minimizes shock loading, which occurs when a load is suddenly jerked or stopped. This reduces stress on equipment and loads, contributing to overall reliability.

In summary, the hydraulic system’s ability to provide high force, precise control, and consistent performance enhances the efficiency and reliability of winching operations across a wide range of industries and applications.

Can you describe the factors to consider when selecting hydraulic winches for specific applications?

Selecting the right hydraulic winch for a specific application involves considering various factors to ensure optimal performance and safety. Here are key factors to take into account:

- 1. Load Capacity: Determine the maximum load the winch will need to handle. Choose a hydraulic winch with a capacity that comfortably exceeds the heaviest load you anticipate. Keep in mind that it’s safer to have a winch with a higher capacity than required.

- 2. Line Speed: Consider the speed at which you need to pull or lift the load. Hydraulic winches offer different line speeds, so choose one that aligns with your application’s requirements. Keep in mind that line speed may vary depending on the load.

- 3. Duty Cycle: Evaluate how frequently and for how long the winch will be in operation. Some winches are designed for continuous use, while others have intermittent duty cycles. Ensure the winch’s duty cycle matches the demands of your application.

- 4. Mounting and Installation: Assess the available space for mounting the winch and the compatibility of the winch’s mounting configuration with your equipment or vehicle. Consider the ease of installation and any additional mounting accessories required.

- 5. Control Options: Determine the level of control you need over the winch. Hydraulic winches may offer manual, remote, or integrated control options. Choose a control method that suits your operational preferences and safety requirements.

- 6. Environmental Conditions: Consider the environmental conditions in which the winch will operate. Hydraulic winches are suitable for various environments, but factors like temperature extremes, exposure to saltwater, and dust levels may influence your choice.

- 7. Safety Features: Check for safety features such as overload protection, emergency stop mechanisms, and fail-safe braking systems. These features enhance operator safety and protect against accidents.

- 8. Cable or Rope Type: Select the appropriate type of cable or rope for your application, considering factors like strength, durability, and compatibility with the winch drum. Ensure that the winch drum can accommodate the chosen cable or rope size.

- 9. Maintenance Requirements: Evaluate the maintenance needs of the hydraulic winch. Some models may require more frequent maintenance than others. Choose a winch that aligns with your maintenance schedule and capabilities.

- 10. Budget Considerations: Set a budget for the hydraulic winch purchase. While it’s essential to meet your application’s requirements, also consider the cost of the winch, installation, and any additional accessories or hydraulic system modifications.

- 11. Brand Reputation and Support: Research and select reputable brands with a history of manufacturing reliable hydraulic winches. Consider the availability of spare parts, technical support, and warranty coverage from the manufacturer.

- 12. Compliance with Standards: Ensure that the selected hydraulic winch complies with relevant industry standards and regulations. This is particularly important in safety-critical applications.

By carefully considering these factors, you can choose the right hydraulic winch that meets the specific requirements of your application, ensuring safe and efficient winching operations.

editor by Dream 2024-05-17

China high quality Sintering Part for Auto Hydraulic Winches

Product Description

Excellent Quality of Our Sintered Powder Metallurgy parts

Our company is producing and exporting wide variety of automotive parts, textile machine, sewing machine, gasoline generator, power tools, oil pump rotor, clutch, oilless bearing, bushings, clutch and so many others with high quality. We can support various powder metallurgy parts including iron, copper, stainless steel and alloy materials based with high quality and reasonable prices. We can also make different sizes and models as the customers’ desired orders.

Over 200 workers are supporting and producing under the control of 3 Professional Engineers who has 20 years experiences in this production. We are always receiving customers’ feedbacks and changing the supplier products as the needs of our customers by special service team.

If you are interested in our products, please do not hesitate to contact us.

Our Products Special Features,

1) Our products passed TS16949 ISO-9001: 2000 quality management system verification

2) Material: Steel, copper, brass, aluminum, Titanium

3) Equipment: CNC lathe, CNC milling machine, CNC high-speed engraving machine, Common machines, laser engraving machines, metal injection machine

4) Precision machining capability:

5) Advanced workmanship, fitting tool, fixture, cutting tool

6) Parts can be supplied according to customers’ drawings or samples.

7) 2D/3D drawings or samples are welcome!

8). Best quality, competitive price, shortest delivery time and good service.

| Place of origin: | ZHangZhoug, China |

| Brand Name: | HangZhou Xihu (West Lake) Dis. Powder Metallurgy Co.,Ltd |

| Type: | Powder metallurgy sintering |

| Surface finish | e-coating, electroplating and black oxygen |

| Measuring method | 3D system, High-lubrication, high-density and high-strength |

| Inspection equipment | Torsion test, voltage feedback test, HRC density test, lifting test and salt spray resistant test and more |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron, stainless steel, copper, Alloy |

| Application: | Automotive parts, power tools, stainless steel, bushings, clutches and so many others |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgy, CNC Machining |

| Powder Metallurgy: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

Powder Metallurgy Component Production Process

A trained, qualified, and dedicated work force

1) Engineering is our strength – we will help your designers convert your parts to cost-effective powdered metal parts.

2) Every employee is trained to a standard of excellence.

Quality is designed into the process

1) Consistent and committed attitude to quality first.

Critical characteristics are measured and controlled using the latest statistical methods

1) Quality is always the first priority.

2) Our subcontractors are held to the same high standards.

OUR FACTORY

Certification

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Electric Winch |

|---|---|

| Power Type: | Permanent-magnet DC |

| Pull Direction: | Forward |

| Manual Winch Type: | Sintered Metal |

| Electric Winch Model: | ATV |

| Working Voltage of Electric Winch: | High Voltage |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there innovations or advancements in hydraulic winch technology that have emerged recently?

Yes, there have been notable innovations and advancements in hydraulic winch technology in recent years. These developments aim to enhance performance, safety, and efficiency in various industries. Some of the key advancements include:

- 1. Electronic Control Systems: Modern hydraulic winches often come equipped with advanced electronic control systems. These systems offer features like load sensing, variable speed control, and remote operation, allowing for precise and convenient winching operations.

- 2. Energy Efficiency: Manufacturers have focused on improving the energy efficiency of hydraulic winches. This includes the use of more efficient hydraulic pumps and components, which can reduce fuel consumption in applications like tow trucks and construction equipment.

- 3. Compact Designs: Advancements in hydraulic system design have resulted in more compact winches that can fit into tighter spaces. This is particularly beneficial in industries where space is limited or where winches need to be integrated into existing equipment.

- 4. Enhanced Safety Features: Recent hydraulic winches often incorporate additional safety features, such as load monitoring, emergency stop systems, and automatic overload protection. These features help prevent accidents and protect equipment.

- 5. Telematics and Data Logging: Some hydraulic winches now feature telematics and data logging capabilities. This allows operators to monitor winch performance, track usage, and perform remote diagnostics, improving maintenance and efficiency.

- 6. Improved Sealing and Corrosion Resistance: Advances in materials and sealing technology have made hydraulic winches more resistant to environmental factors. They can better withstand harsh weather conditions and corrosive environments, extending their lifespan.

- 7. Integration with Vehicle Systems: In industries like towing, hydraulic winches are increasingly integrated with the vehicle’s overall control systems. This integration allows for seamless operation and improved safety features.

- 8. Enhanced Load Control: Innovative hydraulic winches offer improved load control features, including load holding, inching, and precise positioning. These capabilities are particularly valuable in construction and material handling applications.

These recent innovations in hydraulic winch technology aim to address the evolving needs of industries such as construction, towing, and material handling. They contribute to safer, more efficient, and more reliable winching operations.

What maintenance practices are recommended for hydraulic winches to ensure optimal functionality?

Proper maintenance of hydraulic winches is essential to ensure their optimal functionality, extend their service life, and enhance safety. Here are recommended maintenance practices for hydraulic winches:

- 1. Regular Inspection: Conduct routine visual inspections of the winch, including all components, hoses, and fittings. Look for signs of wear, leaks, corrosion, or damage. Inspect the winch drum, cable, and control mechanisms for any issues.

- 2. Lubrication: Ensure that all moving parts are adequately lubricated. Pay special attention to bearings, gears, and pivot points. Lubrication reduces friction, minimizes wear, and ensures smooth operation. Use the recommended lubricants specified by the manufacturer.

- 3. Hydraulic Fluid Checks: Monitor the hydraulic fluid level and condition regularly. Check for leaks in the hydraulic lines and fittings. Maintain the proper hydraulic fluid level and replace or top up fluid as needed with the correct type recommended by the manufacturer.

- 4. Control System Inspection: Examine the winch’s control system, including buttons, switches, and joysticks. Ensure that they function correctly and respond to commands promptly. Clean control surfaces to prevent dirt or debris from interfering with operation.

- 5. Cable Inspection: Inspect the winch cable or rope for signs of wear, fraying, or damage. Replace cables that show wear or damage to prevent accidents during operation. Ensure proper winding on the drum to avoid cable overlap or uneven spooling.

- 6. Brake System Check: If the winch is equipped with a brake system, verify that it engages and disengages properly. The brake system is critical for load control and safety during winching operations.

- 7. Fastener Tightening: Periodically check and tighten all fasteners, bolts, nuts, and hose clamps. Loose fasteners can lead to component failure or hydraulic fluid leaks.

- 8. Filter Maintenance: If the winch has hydraulic filters, follow the manufacturer’s guidelines for filter replacement or cleaning. Clean or replace filters regularly to prevent contamination of the hydraulic system.

- 9. Seal Inspection: Examine hydraulic seals for signs of wear or leaks. Damaged seals can lead to hydraulic fluid leaks and reduced winch performance. Replace seals as needed.

- 10. Electrical System Inspection: If the winch has electrical components, inspect wiring, connectors, and electrical connections for damage or corrosion. Ensure that the electrical system is in good working condition.

- 11. Operator Training: Ensure that operators are properly trained in the use of hydraulic winches. Adequate training can prevent misuse and accidents that may lead to equipment damage or injuries.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their winches, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Professional Service: Consider having the winch professionally inspected and serviced periodically. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, hydraulic winches can operate optimally, promoting safety, reliability, and longevity in various industries and applications.

In what scenarios are hydraulic winches commonly used, and what advantages do they offer?

Hydraulic winches find common use in various scenarios across different industries, thanks to the advantages they offer. Here are scenarios where hydraulic winches are commonly employed and their associated benefits:

- 1. Off-Road and Recovery: Hydraulic winches are extensively used in off-road vehicles, including trucks, jeeps, and ATV/UTVs, for self-recovery and assisting stuck vehicles in challenging terrains. Advantages include their high pulling power and durability in rugged conditions.

- 2. Construction and Material Handling: In construction and material handling, hydraulic winches are employed for lifting heavy materials, positioning equipment, and pulling loads. They offer precise control, high load capacity, and continuous operation, making them indispensable for construction tasks.

- 3. Marine and Maritime: Hydraulic winches play a crucial role in maritime industries for anchor handling, mooring operations, and cargo handling on ships and offshore platforms. They offer resistance to saltwater corrosion and ensure safe vessel operations.

- 4. Oil and Gas: The oil and gas sector relies on hydraulic winches for lifting heavy equipment, handling drilling tools, and controlling rig components during drilling and well servicing operations. They provide strength and reliability in demanding environments.

- 5. Forestry and Logging: In forestry, hydraulic winches are used for skidding and hauling logs. Their robustness and load capacity make them ideal for moving heavy timber through challenging terrain, enhancing efficiency in logging operations.

- 6. Agriculture: Agricultural machinery, such as tractors and combines, may employ hydraulic winches for various applications, including lifting and lowering implements and adjusting equipment height. They contribute to agricultural productivity and versatility.

- 7. Mining: The mining industry uses hydraulic winches for hauling ore, positioning heavy machinery, and handling materials underground. Their ability to withstand harsh mining conditions and handle substantial loads is critical for mining operations.

- 8. Industrial Manufacturing: Manufacturing facilities utilize hydraulic winches for material handling, machinery positioning, and assembly line operations. They offer precise control over movement, improving manufacturing efficiency.

- 9. Utilities and Power Generation: Utilities and power generation companies employ hydraulic winches for tasks like installing utility poles, positioning power line components, and equipment maintenance. They ensure safe and reliable infrastructure operations.

- 10. Emergency Services: Hydraulic winches are vital for fire departments and emergency response teams for vehicle extrication and rescue operations. They assist in freeing trapped individuals and recovering vehicles in emergency situations.

Advantages of hydraulic winches in these scenarios include their exceptional load capacity, precise control, durability, resistance to harsh environments, continuous operation capability, and adaptability to a wide range of tasks. These qualities make hydraulic winches a preferred choice for industries that require heavy-duty and reliable winching solutions.

editor by Dream 2024-05-17

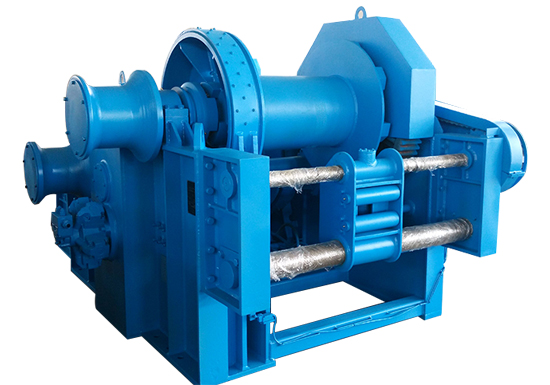

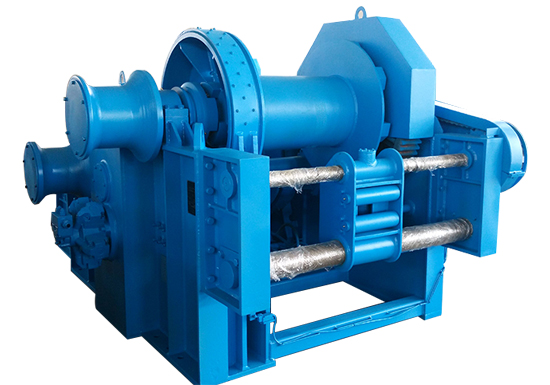

China Best Sales Cheap Price Double Drum High Speed Used Electric Winch Wire Rope Hydraulic Winch for Sale

Product Description

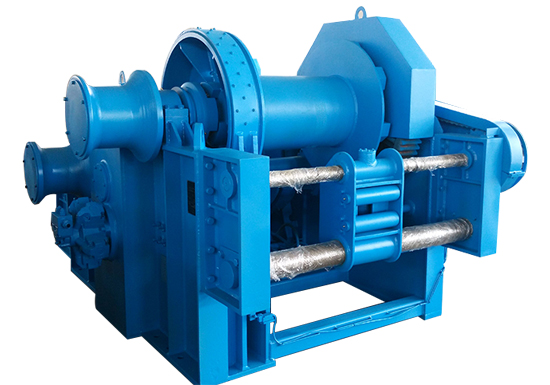

Introduction of Cheap Price Double Drum High Speed Used Electric Winch Wire Rope Hydraulic Winch for Sale

This wire rope electric winch is gear reducer driving winch. This series of electric winch is mainly used for hoisting, pulling and unloading, towing the heavy cargo, such as various types of large and medium sizes of concrete, steel structure, installation and disassembly of mechanical equipment. It’s applicable to civil construction and installation projects of construction and installation enterprises, mining areas and factories, etc.zmwm02

Parameter of Cheap Price Double Drum High Speed Used Electric Winch Wire Rope Hydraulic Winch for Sale

| Model | JSDB-10 | JSDB-12 | JSDB-13 | JSDB-15 | JSDB-16 | JSDB-19 | JSDB-25 | JSDB-30 | |||||||||

| Fast | Slow | Fast | Slow | Fast | Slow | Fast | Slow | Fast | Slow | Fast | Slow | Fast | Slow | Fast | Slow | ||

| Wire rope static tension KN | Outer layer Max. | 14.5 | 100 | 15 | 120 | 15 | 130 | 18 | 150 | 25.4 | 160 | 27.8 | 190 | 30 | 250 | 38 | 300 |

| Inner layer Max. | 22.1 | 140 | 22.1 | 160 | 29.1 | 200 | 30 | 250 | 36.6 | 280 | 43.4 | 320 | 56 | 390 | 56 | 470 | |

| Average | 18.3 | 120 | 18.3 | 140 | 22.05 | 165 | 23 | 200 | 30.5 | 220 | 35.6 | 255 | 43 | 320 | 43 | 380 | |

| Wire Rope speed m/s | Max. | 1.3 | 0.2 | 1.3 | 0.2 | 1.3 | 0.2 | 1.39 | 0.2 | 1.39 | 0.2 | 1.6 | 0.2 | 1.51 | 0.2 | 1.66 | 0.2 |

| Outer layer | |||||||||||||||||

| Average | 1.075 | 0.18 | 1.075 | 0.18 | 1.11 | 0.18 | 1.235 | 0.17 | 1.235 | 0.17 | 1.31 | 0.18 | 4.145 | 0.16 | 1.145 | 0.174 | |

| Drum Size | Wire Rope Length m | 120 | 180 | 180 | 300 | 300 | 500 | 500 | 800 | ||||||||

| Drum Dia.*Width | ф430*430 | ф430*443 | ф435*530 | ф470*530 | ф510*530 | ф545*570 | ф545*760 | ф650*800 | |||||||||

| Wire Rope size | Dia. | 20 | 22 | 24 | 28 | 28 | 30 | 30 | 30 | ||||||||

| Structure | 6*19 | ||||||||||||||||

| Nominal tensile strength kn | 1670 | ||||||||||||||||

| Motor | Type | YBK2-200L1-6 | YBK2-200L2-6 | YBK2-200L2-6 | YBK2-200L2-6 | YBK2-250M-6 | YBK2-280S-6 | YBK2-280M-6 | YBK3-315S-6 | ||||||||

| Power KW | 18.5 | 18.5 | 22 | 22 | 37 | 45 | 55 | 75 | |||||||||

| Revolution rpm | 970 | 970 | 970 | 980 | 980 | 980 | 980 | 980 | |||||||||

| Voltage V | 660/1140 | 660/1140 | 660/1140 | 660/1140 | 660/1140 | 660/1140 | 660/1140 | 660/1140 | |||||||||

| Dimension | L*W*H | 2540*785*800 | 2540*785*800 | 3182*968*987 | 3260*1060*1060 | 3260*1060*1060 | 3825*1214*1470 | 3875*1274*1187 | 4750*1516*1512 | ||||||||

| MM | |||||||||||||||||

| Weight | 2340 | 2600 | 3900 | 4400 | 5000 | 5480 | 7800 | 8200 | |||||||||

| (with motor)(kg) | |||||||||||||||||

Photos of Cheap Price Double Drum High Speed Used Electric Winch Wire Rope Hydraulic Winch for Sale

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | on Line or Video |

|---|---|

| Warranty: | One Year |

| Type: | Electric Winch |

| Samples: |

US$ 7500/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you share tips for selecting the right hydraulic winch based on specific industry requirements and load capacities?

Selecting the right hydraulic winch based on industry requirements and load capacities involves careful consideration of various factors. Here are some tips to help you make an informed choice:

- 1. Determine Load Capacity: Start by assessing the maximum load capacity you need. Consider both the weight of the load and any additional factors like incline or resistance. Choose a winch with a rated capacity that exceeds your requirements to ensure safety and performance.

- 2. Evaluate Line Speed: Different winches offer varying line speeds. Determine the optimal line speed for your application. For precision and control, slower speeds may be suitable, while faster speeds are ideal for rapid retrieval. Ensure the winch you select has the appropriate speed range.

- 3. Consider Duty Cycle: Some winches are designed for intermittent use, while others are built for continuous duty. Evaluate your application’s duty cycle to choose a winch that can handle the expected workload without overheating or excessive wear.

- 4. Assess Environmental Conditions: Take into account the environmental conditions in which the winch will operate. Extreme temperatures, moisture, or corrosive environments may require special seals or coatings for durability. Ensure the winch can withstand the intended environment.

- 5. Review Safety Features: Safety is paramount. Look for winches with safety features such as overload protection, emergency stop mechanisms, and load-holding capabilities. These features enhance safety during winching operations.

- 6. Check Compatibility: Ensure that the chosen hydraulic winch is compatible with the equipment or vehicle it will be mounted on. Compatibility issues can lead to operational problems and reduced reliability.

- 7. Evaluate Control Systems: Consider whether you need advanced control features. Modern hydraulic winches often feature electronic control systems that offer precise control and safety enhancements. Determine if these features are beneficial for your application.

- 8. Review Maintenance Requirements: Assess the ease of maintenance and the availability of replacement parts. Winches with accessible components and manufacturer support are preferable for long-term reliability.

- 9. Consult with Experts: If you’re uncertain about the right winch for your application, consult with industry experts or the manufacturer. They can provide valuable insights and recommendations based on their experience and expertise.

- 10. Consider Future Needs: Anticipate potential changes or future requirements in your industry. Select a winch that can adapt to evolving needs, ensuring a longer lifespan for your investment.

By carefully considering these tips and tailoring your choice to your specific industry requirements and load capacities, you can select the right hydraulic winch that will deliver reliable performance and meet your operational needs.

Can you provide examples of industries or machinery that commonly use hydraulic winches?

Hydraulic winches find extensive use in various industries and are employed in a wide range of machinery and equipment. Here are examples of industries and machinery that commonly use hydraulic winches:

- 1. Construction: Hydraulic winches are integral in construction equipment such as cranes, excavators, and bulldozers for tasks like lifting heavy materials, positioning components, and anchoring loads.

- 2. Marine and Offshore: Ships and offshore platforms use hydraulic winches for anchor handling, mooring, towing, and launching lifeboats. They are essential for maritime operations.

- 3. Mining: In mining operations, hydraulic winches are used for ore extraction, moving heavy machinery, and managing conveyor systems. They play a vital role in the mining industry’s productivity.

- 4. Forestry: Logging equipment, including skidders and forwarders, rely on hydraulic winches for dragging logs and controlling felling operations in rugged forest terrain.

- 5. Oil and Gas: Hydraulic winches are used in drilling rigs, oil exploration, and offshore platforms for lifting and positioning equipment and handling drilling operations.

- 6. Recovery and Towing: Tow trucks and recovery vehicles use hydraulic winches to pull and recover vehicles stuck in various situations, providing roadside assistance and recovery services.

- 7. Agriculture: Agricultural machinery, such as tractors and combine harvesters, may use hydraulic winches for tasks like lifting implements or assisting in heavy-duty agricultural operations.

- 8. Off-Road and 4×4 Vehicles: Off-road enthusiasts and utility vehicles often feature hydraulic winches on their front bumpers to assist in self-recovery and assisting other vehicles in challenging terrain.

- 9. Industrial Manufacturing: Manufacturing facilities utilize hydraulic winches for material handling, moving heavy equipment, and controlling production processes.

- 10. Utilities: Utility trucks, including bucket trucks and digger derricks, use hydraulic winches for lifting personnel and equipment for maintenance and repairs on utility lines and infrastructure.

- 11. Agriculture: Agricultural machinery, such as tractors and combine harvesters, may use hydraulic winches for tasks like lifting implements or assisting in heavy-duty agricultural operations.

- 12. Military and Defense: Military vehicles and equipment employ hydraulic winches for recovery, logistics, and field operations, ensuring mission success in challenging conditions.

These examples illustrate the versatility and importance of hydraulic winches across various industries and applications, where their ability to provide controlled, high-force movement is crucial.

What are the different types and capacities of hydraulic winches available in the market?

The market offers various types and capacities of hydraulic winches to cater to a wide range of applications and industries. Here are some of the common types and their associated capacities:

- 1. Single Drum Hydraulic Winches: These winches have a single drum for winding cable or rope. Capacities can range from a few thousand pounds (e.g., 2,000 lbs) to over 100,000 pounds (e.g., 100,000 lbs). They are used in applications like off-road recovery, construction, and marine operations.

- 2. Double Drum Hydraulic Winches: Double drum winches have two separate drums, allowing for simultaneous winding or unwinding of two cables or ropes. Capacities can vary widely, from around 2,000 lbs to over 200,000 lbs. They find use in applications where dual-line operation is beneficial, such as marine and industrial settings.

- 3. Planetary Hydraulic Winches: Planetary winches use a planetary gear system, which provides high line-pull capacities. Capacities for planetary hydraulic winches can range from 2,000 lbs to well over 100,000 lbs. They are commonly used in industries like construction, mining, and oil and gas.

- 4. Worm Gear Hydraulic Winches: Worm gear winches are known for their high load-holding capability. Capacities typically start at around 2,000 lbs and can exceed 50,000 lbs. They are suitable for applications requiring precise load control, such as lifting heavy equipment and materials.

- 5. Industrial Hydraulic Winches: Industrial hydraulic winches are designed for heavy-duty applications. Capacities for these winches can range from 5,000 lbs to over 100,000 lbs. They are used in manufacturing, forestry, and utilities.

- 6. Marine Hydraulic Winches: Marine winches are specially designed for maritime applications. Capacities vary widely, from a few thousand pounds to over 100,000 lbs. They are used on ships and offshore platforms for anchor handling, mooring, and cargo handling.

- 7. Towing and Recovery Hydraulic Winches: These winches are designed for towing and vehicle recovery. Capacities can range from 5,000 lbs for light-duty applications to over 30,000 lbs for heavy-duty recovery operations.

- 8. Custom Hydraulic Winches: Some manufacturers offer custom hydraulic winches tailored to specific customer requirements. These winches can have capacities that match the exact needs of the application, making them highly versatile.

It’s important to note that the capacity of a hydraulic winch is determined by factors such as the size of the hydraulic motor, the hydraulic system’s pressure, and the design of the winch drum. When selecting a hydraulic winch, it’s crucial to consider the load requirements of the intended application to ensure the winch’s capacity is adequate.

editor by Dream 2024-05-16

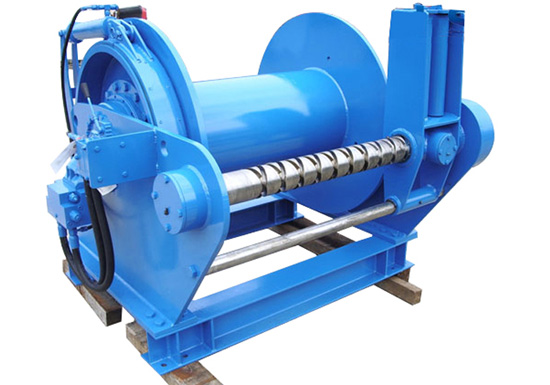

China wholesaler Iacs Approved 10-100ton Ship Electric Hydraulic Towing Winch

Product Description

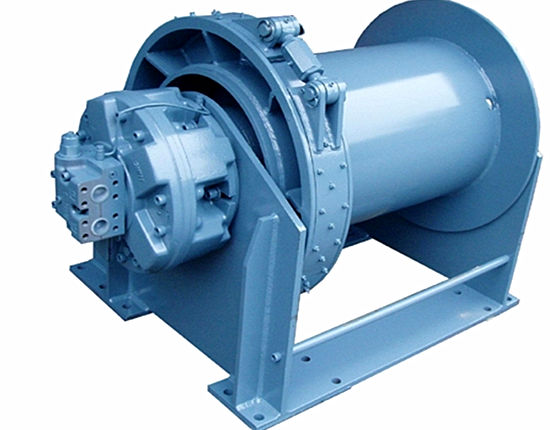

The ship electrical hydraulic towing winch is 1 of the marine equipment used during towing operations to hold a boat in place at a pier or similar fixture. Electric marine mooring capstan can operate effectively when dock ship or docking port, and it has many functions. In the process of loading and unloading, electric driven marine winch plays the role of drift, support and positioning, and adjusts the deviation of compensation vibration with constant tension.

The marine towing winch can be driven by electric and hydraulic. As you can see our below electric driven type marine mooring winch. The rated pull is from 5KN to 650KN. CHINAMFG marine can design the electronic ship mooring winchaccording to your specific requirement.

All our marine winches are approved by CCS,ABS,DNV,BV,NK,RINA,BKI. GOHI marine can offer you the marine winch capstan with hight quality and best price. Pls feel free to contact ZheJiang Gohi marine sales team for more details.

Towing winch is widely used in tugboat. Single drum, double drums are available.

For double drums, waterfall configuration is the normal selection. The lower drum is used for anchoring, the upper used for towing.

The nominal speed depend on working load of winch, larger load with slower speed.

Usually the speed is around 3-10m/min, the drum capacity is about 500-1500m.

Spooling device is optional.

Electric driven mode is used for smaller towing winch and hydraulic for big winch.

Local control stands and remote control panel are optional.

Emergency release system is required as per class rules..

The rope length and tension display and constant tension are available.

Braking force =working load*3

Bollard pull=HP/10=KN

Nominal pull=bollard pull*1.5

| Model | Drum Load (KN) | Nominal Speed (m/min) | Holding Load (KN) | Dia. Of Rope (mm) | Rope Capacity (m) |

| GH-30 | 30 | 15 | 90 | 16 | 150 |

| GH-40 | 40 | 15 | 120 | 18 | 150 |

| GH-50 | 50 | 15 | 150 | 20 | 180 |

| GH-75 | 75 | 15 | 220 | 26 | 180 |

| GH-80 | 80 | 15 | 240 | 26 | 200 |

| GH-100 | 100 | 15 | 300 | 28 | 200 |

| GH-125 | 125 | 15 | 310 | 30 | 200 |

| GH-150 | 150 | 15 | 450 | 32 | 250 |

| GH-160 | 160 | 15 | 470 | 32 | 250 |

| GH-200 | 200 | 9.6 | 590 | 40 | 250 |

| GH-250 | 250 | 9.6 | 730 | 44 | 250 |

| GH-315 | 315 | 7.8 | 940 | 52 | 250 |

| GH-350 | 350 | 7.8 | 1050 | 54 | 250 |

| GH-400 | 400 | 7.8 | 1050 | 56 | 250 |

Towing winches mainly used for oversize concrete construction of steel installation and disassembly of mechanical equipment. The wire rope ordered arrangement. Lifting is safe and reliable. It is suitable for bridge, factory, harbor, wharf etc. Gear reducer driving, Used for hoisting, pulling, drag, compact structure, stable running.

Advantages and main featrues:

1. Top quality with competitive price.

2. Widely used in factory, mining, shipyard or double beam cranes.

3. Compact structure and reasonable design.

4. Easy to install, operate and maintenance.

5. Low noise and good working condition.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | World Wide |

|---|---|

| Operation Form: | Ships |

| Warranty: | 1 Year |

| Certification: | Cc,BV, ABS, Dnv-Gl |

| Material: | Stainless Steel |

| Load Capacity: | 10-1000kn |

| Customization: |

Available

|

|

|---|

What safety considerations should be taken into account when using hydraulic winches in various settings?

Using hydraulic winches in different settings requires careful attention to safety measures to prevent accidents and ensure the well-being of operators and others nearby. Here are important safety considerations:

- 1. Operator Training: Ensure that operators are properly trained in the operation of hydraulic winches. Training should cover the safe use of controls, emergency procedures, and an understanding of the winch’s load capacity and limitations.

- 2. Equipment Inspection: Conduct pre-use inspections to check the winch and associated equipment for signs of wear, damage, or malfunction. Look for issues with cables, hydraulic lines, controls, and safety mechanisms.

- 3. Load Rating: Always respect the winch’s load rating and capacity. Avoid overloading the winch, as this can lead to equipment failure and accidents. Refer to the winch’s documentation for load limits.

- 4. Secure Mounting: Ensure that the winch is securely and properly mounted to the equipment or vehicle. Loose or improper mounting can lead to accidents and equipment damage during operation.

- 5. Cable Inspection: Regularly inspect the winch cable for signs of wear, fraying, or damage. Replace damaged cables promptly to prevent accidents caused by cable failure.

- 6. Controlled Operation: Operate the winch smoothly and with control. Avoid abrupt starts and stops that can cause shock loading and endanger safety. Use variable line speed settings for precision.

- 7. Load Control: Use appropriate load control techniques, such as load-holding or inching, to ensure that loads are lifted, pulled, or lowered in a controlled manner. Prevent sudden and unexpected movements.

- 8. Remote Control: Whenever possible, operate the hydraulic winch from a safe distance using remote controls. This minimizes the risk to operators in case of unexpected load movement.

- 9. Emergency Stop: Familiarize operators with the emergency stop procedures and mechanisms of the hydraulic winch. Ensure that they know how to quickly stop the winch in case of emergencies or malfunctions.

- 10. Regular Maintenance: Follow a routine maintenance schedule recommended by the manufacturer. Regular maintenance checks for leaks, worn components, and overall winch condition. Address any issues promptly.

- 11. Hydraulic Fluid: Monitor hydraulic fluid levels and quality. Keep hydraulic fluid clean and at the recommended level to ensure proper winch operation. Address hydraulic leaks promptly to prevent fluid contamination.

- 12. Environmental Considerations: Be aware of the environmental conditions in which the winch is used. Extreme temperatures, moisture, and corrosive environments can affect the winch’s performance and safety. Consider environmental factors in maintenance and operation.

- 13. Communication: Establish clear communication protocols among team members involved in winching operations. This ensures that everyone is aware of the plan, roles, and safety procedures.

- 14. Regulatory Compliance: Be aware of and comply with safety regulations and standards specific to your industry and location. Compliance helps ensure safe winch operation and prevents regulatory issues.

Adhering to these safety considerations when using hydraulic winches is essential to prevent accidents, protect personnel, and maintain the integrity of equipment. Safety should always be a top priority in winching operations.

Can hydraulic winches be customized for specific load capacities or environmental conditions?

Yes, hydraulic winches can often be customized to meet specific load capacities and environmental conditions, making them versatile solutions for various industries and applications. Here’s how customization can be achieved:

- 1. Load Capacity: Hydraulic winches can be customized to accommodate different load capacities. Manufacturers can adjust the size and specifications of hydraulic components, such as the hydraulic motor and winch drum, to match the required load capacity. Custom-built winches can handle loads ranging from a few thousand pounds to several hundred thousand pounds.

- 2. Line Speed: Customization allows for the adjustment of line speed to meet specific application requirements. Depending on the hydraulic system’s design, modifications can be made to achieve faster or slower line speeds while maintaining control and safety.

- 3. Environmental Adaptations: Hydraulic winches can be customized to operate in various environmental conditions. For applications in extreme temperatures, winches can be equipped with specialized seals, coolers, or heaters to ensure proper hydraulic fluid temperature regulation. In corrosive environments, winches can be coated or made from materials that resist corrosion.

- 4. Control Systems: Custom control systems can be integrated into hydraulic winches to provide precise control and automation. This allows operators to tailor winch operation to specific tasks, enhancing efficiency and safety.

- 5. Mounting Configurations: Hydraulic winches can be customized to fit different mounting configurations. Whether it’s for a vehicle, equipment, or a fixed installation, manufacturers can design winches with mounting options that align with the customer’s requirements.

- 6. Safety Features: Custom hydraulic winches can include additional safety features or fail-safes to meet specific safety standards or regulations. These features may include emergency stop systems, load monitoring, or remote control options.

- 7. Duty Cycle: Winches can be tailored to have the appropriate duty cycle, whether for continuous operation or intermittent use. Customization ensures that the winch can meet the application’s operational demands without overheating or downtime.

Custom hydraulic winches are often developed in collaboration with manufacturers or engineering teams to ensure that they precisely match the requirements of the application. These customized solutions provide reliability, efficiency, and safety in diverse industries, including construction, mining, marine, and more.

What are the different types and capacities of hydraulic winches available in the market?

The market offers various types and capacities of hydraulic winches to cater to a wide range of applications and industries. Here are some of the common types and their associated capacities:

- 1. Single Drum Hydraulic Winches: These winches have a single drum for winding cable or rope. Capacities can range from a few thousand pounds (e.g., 2,000 lbs) to over 100,000 pounds (e.g., 100,000 lbs). They are used in applications like off-road recovery, construction, and marine operations.

- 2. Double Drum Hydraulic Winches: Double drum winches have two separate drums, allowing for simultaneous winding or unwinding of two cables or ropes. Capacities can vary widely, from around 2,000 lbs to over 200,000 lbs. They find use in applications where dual-line operation is beneficial, such as marine and industrial settings.

- 3. Planetary Hydraulic Winches: Planetary winches use a planetary gear system, which provides high line-pull capacities. Capacities for planetary hydraulic winches can range from 2,000 lbs to well over 100,000 lbs. They are commonly used in industries like construction, mining, and oil and gas.

- 4. Worm Gear Hydraulic Winches: Worm gear winches are known for their high load-holding capability. Capacities typically start at around 2,000 lbs and can exceed 50,000 lbs. They are suitable for applications requiring precise load control, such as lifting heavy equipment and materials.

- 5. Industrial Hydraulic Winches: Industrial hydraulic winches are designed for heavy-duty applications. Capacities for these winches can range from 5,000 lbs to over 100,000 lbs. They are used in manufacturing, forestry, and utilities.

- 6. Marine Hydraulic Winches: Marine winches are specially designed for maritime applications. Capacities vary widely, from a few thousand pounds to over 100,000 lbs. They are used on ships and offshore platforms for anchor handling, mooring, and cargo handling.

- 7. Towing and Recovery Hydraulic Winches: These winches are designed for towing and vehicle recovery. Capacities can range from 5,000 lbs for light-duty applications to over 30,000 lbs for heavy-duty recovery operations.

- 8. Custom Hydraulic Winches: Some manufacturers offer custom hydraulic winches tailored to specific customer requirements. These winches can have capacities that match the exact needs of the application, making them highly versatile.

It’s important to note that the capacity of a hydraulic winch is determined by factors such as the size of the hydraulic motor, the hydraulic system’s pressure, and the design of the winch drum. When selecting a hydraulic winch, it’s crucial to consider the load requirements of the intended application to ensure the winch’s capacity is adequate.

editor by Dream 2024-05-16

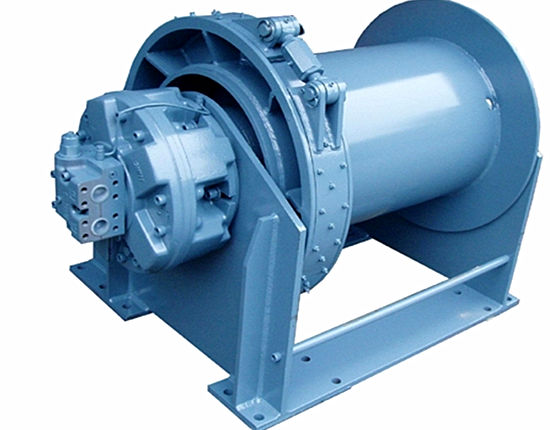

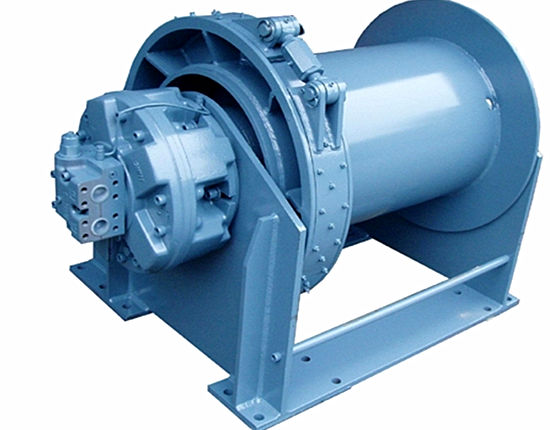

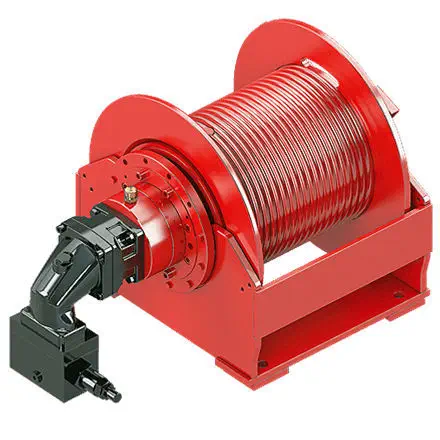

China best Hydraulic Winch for Truck Pulling and Lifting 10kn20kn30kn

Product Description

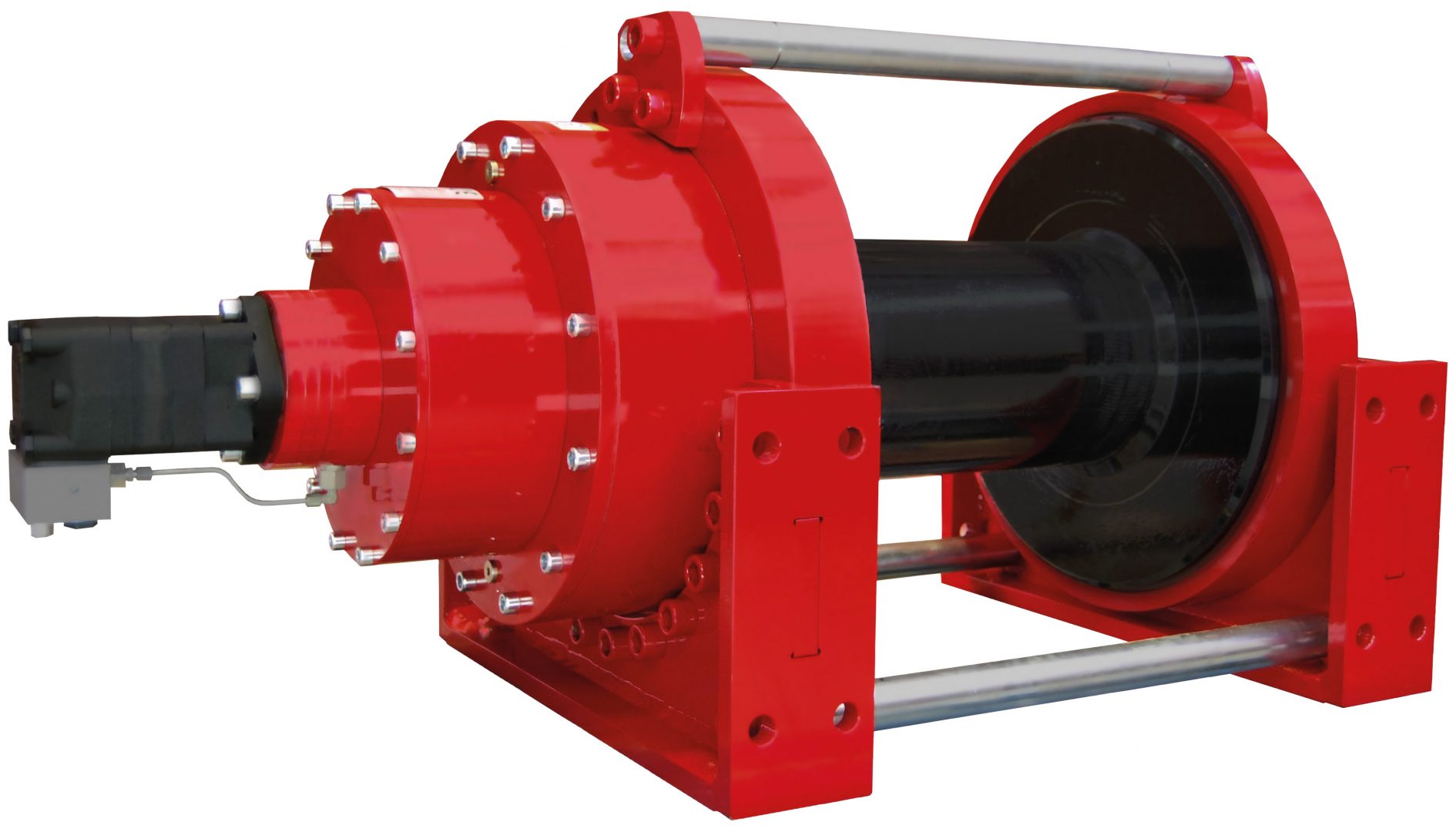

Hydraulic winch including the orbital motors, planetary gear reducer and brakes and other components.Using rebar steel frame connections, configure the shuttle valve,balance valve and other security control systems,compact structure, small volume .Applies to ships, piers,construction machinery and other lifting and pulling devices.

Reel clockwise to rise up

2.Winch brake using the multi-disc brake

3.Winches with planetary gear reducer, run steady, compact and reasonable.

4.Internally lubricated with grease lubrication

5.Maximum return oil back pressure 5bar

6.To ensure safety,keep at least 4 laps rope on the roll wrapped around 7.Please use above8.8 bolts(M16above) fix winch

8.we can supply the pull range have 1MT,1.5MT,2MT,2.5MTand 3MT

Stable Supply: We will strengthen our supply chain management to ensure timely delivery and maintain the consistency and quality of our goods.

Product Quality: Each batch of our products undergoes rigorous quality checks to meet your requirements and standards.

Customization: Your needs are of utmost importance to us. If you have any specific customization requirements, please feel free to let us know, and we will do our best to fulfill them.

Excellent Service: Our team will continue to provide professional pre-sales consultation and after-sales support to address any concerns and ensure your utmost satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | More Than One Year |

|---|---|

| Warranty: | More Than One Year |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | Slow |

| Carrying Capacity: | Light Level |

| Customization: |

Available

|

|

|---|

Can you explain the impact of hydraulic winches on the overall safety of lifting and pulling tasks?

Hydraulic winches significantly impact the overall safety of lifting and pulling tasks across various industries. Their design and features contribute to enhanced safety in the following ways:

- 1. Precise Control: Hydraulic winches provide operators with precise control over load movement. The ability to vary line speed and direction accurately ensures that loads can be positioned and moved safely without abrupt or unpredictable movements.

- 2. Variable Line Speed: Hydraulic winches offer variable line speed control, allowing operators to adjust the speed according to the task’s requirements. This adaptability is crucial for safely handling different loads and situations, preventing sudden jolts or over-speeding.

- 3. Overload Protection: Many hydraulic winches are equipped with overload protection mechanisms. These features prevent the winch from exerting excessive force beyond its capacity, reducing the risk of equipment damage or failure. Overload protection ensures safe operation even when loads unexpectedly become too heavy.

- 4. Smooth Operation: Hydraulic systems provide smooth and consistent operation, minimizing jerky movements or sudden stops. This reduces the risk of shock-loading, which can lead to equipment stress and load instability, posing safety hazards.

- 5. High Force Output: Hydraulic winches generate high torque and force, allowing them to handle heavy loads efficiently. This high force capability ensures that loads can be controlled and moved safely, even in challenging conditions.

- 6. Consistent Performance: Hydraulic systems maintain a constant force output regardless of load variations. This consistency ensures that the winch performs predictably and safely, reducing the likelihood of accidents due to unexpected changes in load force.

- 7. Operator Safety: The ability to control hydraulic winches remotely or from a safe distance enhances operator safety. Operators can maintain a safe distance from the load, reducing the risk of injury in case of unexpected load movement.

- 8. Durability: Hydraulic winches are known for their durability and resistance to wear and tear. Properly maintained hydraulic systems have a longer service life, reducing the need for frequent replacements and associated risks during installation or maintenance.

- 9. Adaptability to Environmental Conditions: Hydraulic winches can be customized with features such as special seals, coolers, or heaters to adapt to various environmental conditions. This ensures that the winch functions safely and reliably in extreme temperatures or corrosive environments.

- 10. Operator Training: Adequate operator training is crucial for safe winch operation. Training ensures that operators understand the winch’s capabilities and limitations, as well as safety procedures, preventing accidents caused by misuse.

Overall, hydraulic winches provide a level of safety that is critical in industries where lifting and pulling tasks involve heavy loads, precise positioning, and potentially hazardous environments. Their ability to offer controlled, high-force movements enhances safety for both operators and equipment.

How does the hydraulic system impact the overall efficiency and reliability of winching operations?

The hydraulic system plays a significant role in enhancing the efficiency and reliability of winching operations. Its impact is substantial, making hydraulic winches preferred choices in various applications. Here’s how the hydraulic system contributes to overall efficiency and reliability:

- 1. High Force Output: Hydraulic winches can generate high force, thanks to the hydraulic fluid’s incompressible nature. This high force allows them to handle heavy loads efficiently and overcome resistance, making them reliable for challenging tasks.

- 2. Precise Control: Hydraulic systems provide precise control over winching operations. Operators can finely adjust the speed and direction of movement, allowing for accurate positioning and controlled lifting or pulling. This precision minimizes the risk of accidents and damage to equipment or loads.

- 3. Consistent Performance: Hydraulic systems offer consistent performance, regardless of load variations. The hydraulic pump maintains a constant flow of fluid, ensuring that the winch operates at a consistent speed and force. This consistency is crucial for reliable and predictable operations.

- 4. Variable Line Speed: Hydraulic winches offer variable line speed control. By adjusting the flow rate of hydraulic fluid, operators can vary the winch’s speed to match specific requirements. This adaptability improves efficiency in tasks with varying speed demands.

- 5. Overload Protection: Many hydraulic winches are equipped with overload protection mechanisms. These safety features prevent the winch from exerting excessive force beyond its capacity, reducing the risk of equipment damage or failure. Overload protection enhances the reliability of winching operations.

- 6. Durability and Longevity: Hydraulic systems are known for their durability and longevity. They can withstand heavy use and harsh environmental conditions. Properly maintained hydraulic winches can have a long service life, reducing downtime and replacement costs.

- 7. Low Heat Buildup: Hydraulic systems produce less heat during operation compared to electric winches. Lower heat buildup reduces the risk of overheating and extends the life of hydraulic components, contributing to reliability.

- 8. Adaptability to Environmental Conditions: Hydraulic winches can be adapted to various environmental conditions. Special seals, coolers, or heaters can be added to ensure proper hydraulic fluid temperature regulation, making them reliable in extreme temperatures or corrosive environments.

- 9. Reduced Shock Loading: The smooth and controlled operation of hydraulic winches minimizes shock loading, which occurs when a load is suddenly jerked or stopped. This reduces stress on equipment and loads, contributing to overall reliability.

In summary, the hydraulic system’s ability to provide high force, precise control, and consistent performance enhances the efficiency and reliability of winching operations across a wide range of industries and applications.

In what scenarios are hydraulic winches commonly used, and what advantages do they offer?

Hydraulic winches find common use in various scenarios across different industries, thanks to the advantages they offer. Here are scenarios where hydraulic winches are commonly employed and their associated benefits:

- 1. Off-Road and Recovery: Hydraulic winches are extensively used in off-road vehicles, including trucks, jeeps, and ATV/UTVs, for self-recovery and assisting stuck vehicles in challenging terrains. Advantages include their high pulling power and durability in rugged conditions.

- 2. Construction and Material Handling: In construction and material handling, hydraulic winches are employed for lifting heavy materials, positioning equipment, and pulling loads. They offer precise control, high load capacity, and continuous operation, making them indispensable for construction tasks.

- 3. Marine and Maritime: Hydraulic winches play a crucial role in maritime industries for anchor handling, mooring operations, and cargo handling on ships and offshore platforms. They offer resistance to saltwater corrosion and ensure safe vessel operations.

- 4. Oil and Gas: The oil and gas sector relies on hydraulic winches for lifting heavy equipment, handling drilling tools, and controlling rig components during drilling and well servicing operations. They provide strength and reliability in demanding environments.

- 5. Forestry and Logging: In forestry, hydraulic winches are used for skidding and hauling logs. Their robustness and load capacity make them ideal for moving heavy timber through challenging terrain, enhancing efficiency in logging operations.

- 6. Agriculture: Agricultural machinery, such as tractors and combines, may employ hydraulic winches for various applications, including lifting and lowering implements and adjusting equipment height. They contribute to agricultural productivity and versatility.

- 7. Mining: The mining industry uses hydraulic winches for hauling ore, positioning heavy machinery, and handling materials underground. Their ability to withstand harsh mining conditions and handle substantial loads is critical for mining operations.

- 8. Industrial Manufacturing: Manufacturing facilities utilize hydraulic winches for material handling, machinery positioning, and assembly line operations. They offer precise control over movement, improving manufacturing efficiency.

- 9. Utilities and Power Generation: Utilities and power generation companies employ hydraulic winches for tasks like installing utility poles, positioning power line components, and equipment maintenance. They ensure safe and reliable infrastructure operations.

- 10. Emergency Services: Hydraulic winches are vital for fire departments and emergency response teams for vehicle extrication and rescue operations. They assist in freeing trapped individuals and recovering vehicles in emergency situations.

Advantages of hydraulic winches in these scenarios include their exceptional load capacity, precise control, durability, resistance to harsh environments, continuous operation capability, and adaptability to a wide range of tasks. These qualities make hydraulic winches a preferred choice for industries that require heavy-duty and reliable winching solutions.

editor by Dream 2024-05-16

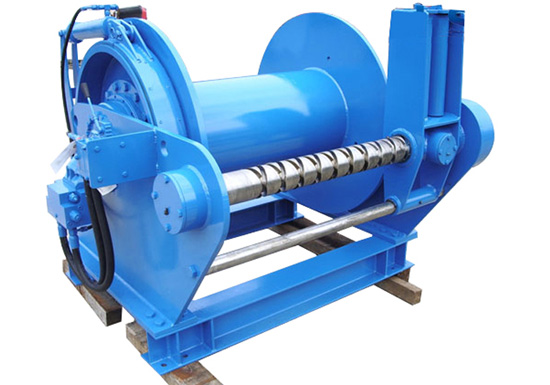

China OEM Hydraulic Winch for Tractor/ Truck/Boom/Marine/Crane

Product Description

1 YEAR WARRANTY AND EXCELLENT SERVICE

7 DAYS REFUND PAYMENT IN CASE OF QUALITY

24 HOURS SMOOTHLY COMMUNICATION

Product Description

|

Model NO: |

tractor/ truck/boom/marine/crane |

|

Type: |

Hydraulic Windlass |

|

Driven Type: |

Hydraulic |

|

Carrying Capacity: |

Special Weight Level |

|

Speed: |

Slow |

|

Reel Number: |

2 |

|

Standard: |

Nonstandard |

|

Rated Pull: |

500 Kn |

|

Nomial Speed: |

≥7 M/Min |

|

Motor Power: |

200 Kw |

|

Drum Capacity: |

600 M |

|

Origin: |

ZHangZhoug |

Detailed Photos

Company Profile

FAQ

Q: Are you trading company or manufacturer?

A: We are factory with more than 20 years experience.

Q: How long for delivery?

A: Generally it is 15-30days as we are customized service we confirm with customer when place order.

Q: What is the MOQ?

A: It depends on what you are buying. Normally, our minimum order is 1 20′ full container and LCL container (less than a

container load) can be acceptable.

Q: Can you customize my products?

A: Yes, we can customized products with your design drawings like DWG, DXF, DXW, IGES, STEP, PDF etc.

Q: What is your terms of payment?

A: 30% T/T in advance, balance before shipment, or as per discussion.

Q: What about your quality control?

A: * . Checking the raw material after they reach our factory—–Incoming quality control(IQC)

* . Checking the details before the production line operated

* . Have full inspection and routing inspection during mass production—-In-process quality control(IPQC)

* . Checking the goods after they are finished—-Final quality control(FQC)

* . Checking the goods after they are finished—-Outgoing quality control(QC)

* . 100% inspection and delivery before shipment

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Electric Winch |

| Driven Type: | Hydraulic |

| Speed: | Slow |

| Carrying Capacity: | Special Weight Level |

| Customization: |

Available

|

|

|---|