Product Description

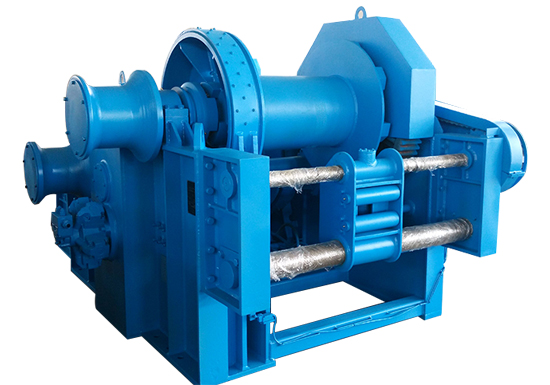

Two-Chain Lifter Hydraulic Combined Windlass

Marine Anchor Windlass is a machine that was designed to raise and lower the anchor by means of anchor chain.; It makes use of an intergral gearbos and motor assembly,; all typically located above deck with a horizontal shaft through the unit and wheels for chain and/or rope on the other side.;

All windlass are approved by ABS,; LR,; DNV,; BV,; RINA,; etc and could be designed and manufactured by your requirements.;

Inquire Now

PRODUCT INTRODUCTION

| Two-chain Lifter Hydraulic Combined Windlass | |||||||||

| Type | Anchor chain dia.; (mm); | Working load (KN); | Over Load (KN); | Loading Support(KN); | Nominal speed (m/min); | Mooring line load (KN); | |||

| AM2 | AM3 | AM2 | AM3 | AM2 | AM3 | ||||

| YMA-17.;5 | 17.;5 | 13 | 14.;6 | 19.;5 | 21.;9 | 80 | 115 | 9 | 30 |

| YMA-19 | 19 | 15.;3 | 17.;2 | 23 | 25.;8 | 95 | 135 | 9 | 10 |

| YMA-20 | 20 | 17.;9 | 20 | 26.;9 | 30 | 110 | 157 | 9 | 10 |

| YMA-22 | 22 | 20.;6 | 23 | 30.;9 | 34.;5 | 126 | 180 | 9 | 15 |

| YMA-24 | 24 | 24.;5 | 27.;4 | 36.;8 | 41.;1 | 149 | 214 | 9 | 20 |

| YMA-26 | 26 | 28.;7 | 32.;1 | 43.;1 | 48.;2 | 175 | 250 | 9 | 20 |

| YMA-28 | 28 | 33.;3 | 37.;2 | 50 | 55.;8 | 202 | 289 | 9 | 20 |

| YMA-30 | 30 | 38.;3 | 42.;8 | 57.;5 | 64.;2 | 231 | 330 | 9 | 30 |

| YMA-32 | 32 | 43.;5 | 48.;6 | 65.;3 | 72.;9 | 261 | 374 | 9 | 30 |

| YMA-34 | 34 | 49.;1 | 54.;9 | 73.;3 | 82.;4 | 294 | 421 | 9 | 30 |

| YMA-36 | 36 | 55.;1 | 61.;6 | 82.;7 | 92.;4 | 329 | 470 | 9 | 30 |

| YMA-38 | 38 | 61.;4 | 68.;9 | 92.;1 | 103.;4 | 365 | 522 | 9 | 40 |

| YMA-40 | 40 | 68 | 76 | 102 | 114 | 402 | 576 | 9 | 40 |

| YMA-42 | 42 | 75 | 83.;8 | 112.;5 | 125.;7 | 442 | 632 | 9 | 50 |

| YMA-44 | 44 | 82.;3 | 92 | 123.;5 | 138 | 483 | 691 | 9 | 50 |

| YMA-46 | 46 | 89.;9 | 100.;5 | 134.;9 | 150.;8 | 526 | 753 | 9 | 50 |

| YMA-48 | 48 | 97.;9 | 109.;4 | 146.;9 | 164.;1 | 570 | 816 | 9 | 50 |

| YMA-50 | 50 | 106.;3 | 118.;8 | 159.;5 | 178.;2 | 617 | 882 | 9 | 50 |

| Transport Package: | Standard Export Package or as Customers′ Specific |

|---|---|

| Specification: | 14~150mm |

| Trademark: | zhenjiang star |

| Origin: | China |

| Customization: |

Available

|

|

|---|

What safety considerations should be taken into account when using hydraulic winches in various settings?

Using hydraulic winches in different settings requires careful attention to safety measures to prevent accidents and ensure the well-being of operators and others nearby. Here are important safety considerations:

- 1. Operator Training: Ensure that operators are properly trained in the operation of hydraulic winches. Training should cover the safe use of controls, emergency procedures, and an understanding of the winch’s load capacity and limitations.

- 2. Equipment Inspection: Conduct pre-use inspections to check the winch and associated equipment for signs of wear, damage, or malfunction. Look for issues with cables, hydraulic lines, controls, and safety mechanisms.

- 3. Load Rating: Always respect the winch’s load rating and capacity. Avoid overloading the winch, as this can lead to equipment failure and accidents. Refer to the winch’s documentation for load limits.

- 4. Secure Mounting: Ensure that the winch is securely and properly mounted to the equipment or vehicle. Loose or improper mounting can lead to accidents and equipment damage during operation.

- 5. Cable Inspection: Regularly inspect the winch cable for signs of wear, fraying, or damage. Replace damaged cables promptly to prevent accidents caused by cable failure.

- 6. Controlled Operation: Operate the winch smoothly and with control. Avoid abrupt starts and stops that can cause shock loading and endanger safety. Use variable line speed settings for precision.

- 7. Load Control: Use appropriate load control techniques, such as load-holding or inching, to ensure that loads are lifted, pulled, or lowered in a controlled manner. Prevent sudden and unexpected movements.

- 8. Remote Control: Whenever possible, operate the hydraulic winch from a safe distance using remote controls. This minimizes the risk to operators in case of unexpected load movement.

- 9. Emergency Stop: Familiarize operators with the emergency stop procedures and mechanisms of the hydraulic winch. Ensure that they know how to quickly stop the winch in case of emergencies or malfunctions.

- 10. Regular Maintenance: Follow a routine maintenance schedule recommended by the manufacturer. Regular maintenance checks for leaks, worn components, and overall winch condition. Address any issues promptly.

- 11. Hydraulic Fluid: Monitor hydraulic fluid levels and quality. Keep hydraulic fluid clean and at the recommended level to ensure proper winch operation. Address hydraulic leaks promptly to prevent fluid contamination.

- 12. Environmental Considerations: Be aware of the environmental conditions in which the winch is used. Extreme temperatures, moisture, and corrosive environments can affect the winch’s performance and safety. Consider environmental factors in maintenance and operation.

- 13. Communication: Establish clear communication protocols among team members involved in winching operations. This ensures that everyone is aware of the plan, roles, and safety procedures.

- 14. Regulatory Compliance: Be aware of and comply with safety regulations and standards specific to your industry and location. Compliance helps ensure safe winch operation and prevents regulatory issues.

Adhering to these safety considerations when using hydraulic winches is essential to prevent accidents, protect personnel, and maintain the integrity of equipment. Safety should always be a top priority in winching operations.

How does the hydraulic system impact the overall efficiency and reliability of winching operations?

The hydraulic system plays a significant role in enhancing the efficiency and reliability of winching operations. Its impact is substantial, making hydraulic winches preferred choices in various applications. Here’s how the hydraulic system contributes to overall efficiency and reliability:

- 1. High Force Output: Hydraulic winches can generate high force, thanks to the hydraulic fluid’s incompressible nature. This high force allows them to handle heavy loads efficiently and overcome resistance, making them reliable for challenging tasks.

- 2. Precise Control: Hydraulic systems provide precise control over winching operations. Operators can finely adjust the speed and direction of movement, allowing for accurate positioning and controlled lifting or pulling. This precision minimizes the risk of accidents and damage to equipment or loads.

- 3. Consistent Performance: Hydraulic systems offer consistent performance, regardless of load variations. The hydraulic pump maintains a constant flow of fluid, ensuring that the winch operates at a consistent speed and force. This consistency is crucial for reliable and predictable operations.

- 4. Variable Line Speed: Hydraulic winches offer variable line speed control. By adjusting the flow rate of hydraulic fluid, operators can vary the winch’s speed to match specific requirements. This adaptability improves efficiency in tasks with varying speed demands.

- 5. Overload Protection: Many hydraulic winches are equipped with overload protection mechanisms. These safety features prevent the winch from exerting excessive force beyond its capacity, reducing the risk of equipment damage or failure. Overload protection enhances the reliability of winching operations.

- 6. Durability and Longevity: Hydraulic systems are known for their durability and longevity. They can withstand heavy use and harsh environmental conditions. Properly maintained hydraulic winches can have a long service life, reducing downtime and replacement costs.

- 7. Low Heat Buildup: Hydraulic systems produce less heat during operation compared to electric winches. Lower heat buildup reduces the risk of overheating and extends the life of hydraulic components, contributing to reliability.

- 8. Adaptability to Environmental Conditions: Hydraulic winches can be adapted to various environmental conditions. Special seals, coolers, or heaters can be added to ensure proper hydraulic fluid temperature regulation, making them reliable in extreme temperatures or corrosive environments.

- 9. Reduced Shock Loading: The smooth and controlled operation of hydraulic winches minimizes shock loading, which occurs when a load is suddenly jerked or stopped. This reduces stress on equipment and loads, contributing to overall reliability.

In summary, the hydraulic system’s ability to provide high force, precise control, and consistent performance enhances the efficiency and reliability of winching operations across a wide range of industries and applications.

How does the hydraulic system contribute to the operation and power of hydraulic winches?

The hydraulic system plays a fundamental role in the operation and power of hydraulic winches. It provides the necessary force and control to perform winching tasks effectively. Here’s how the hydraulic system contributes to hydraulic winch operation:

- 1. Power Source: The hydraulic system of a hydraulic winch is typically powered by an external source, such as a hydraulic pump connected to an engine or a hydraulic power unit (HPU). This source generates hydraulic pressure, which is transmitted to the winch.

- 2. Hydraulic Fluid: Hydraulic fluid, usually hydraulic oil, is the medium that transmits power within the hydraulic system. When pressurized, the hydraulic fluid transfers force to the winch’s hydraulic motor, creating motion.

- 3. Hydraulic Motor: The hydraulic motor is a key component of the hydraulic winch. It converts the hydraulic pressure from the fluid into mechanical rotation. This rotation powers the winch drum, which winds or unwinds the cable or rope.

- 4. Control Valves: Control valves within the hydraulic system regulate the flow of hydraulic fluid to the hydraulic motor. These valves enable precise control over the winch’s speed, direction, and force. Operators can adjust these parameters as needed for the specific winching task.

- 5. High Torque Output: Hydraulic winches are known for their high torque output, which makes them capable of handling heavy loads. The hydraulic system’s ability to generate and control high pressure contributes to this torque, enabling the winch to exert substantial pulling or lifting force.

- 6. Continuous Operation: Hydraulic winches can operate continuously without overheating. The hydraulic system’s design ensures efficient heat dissipation, allowing for prolonged operation without the need for cooldown periods. This is crucial for tasks that require sustained winching.

- 7. Adaptability to Varied Loads: The hydraulic system’s pressure can be adjusted to suit different load requirements. This adaptability makes hydraulic winches versatile, capable of handling a wide range of loads with precision.

- 8. Reliability in Harsh Environments: Hydraulic systems are known for their durability and reliability in harsh environments. They are less susceptible to damage from factors like dust, moisture, and temperature extremes compared to electrical systems.

In summary, the hydraulic system provides the power, control, and reliability that hydraulic winches require for their operation. It enables these winches to exert high torque, adapt to various loads, offer precise control, and operate continuously, making them essential tools for heavy-duty winching tasks in diverse industries.

editor by CX 2023-12-14