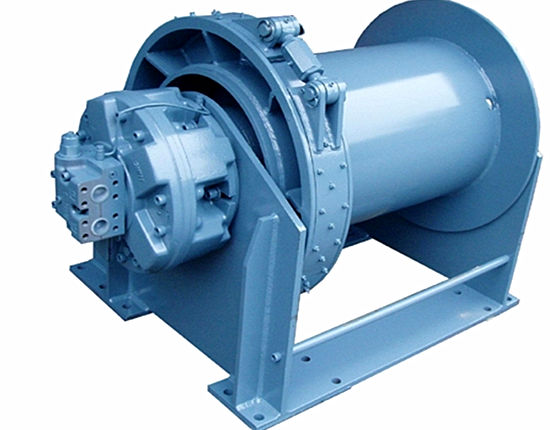

Product Description

Parameter:

| Model | QLW455-12) |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Support |

|---|---|

| Warranty: | One Year |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | Fast |

| Carrying Capacity: | Middle-Level |

| Samples: |

US$ 10000/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic winches contribute to heavy-duty applications such as towing or construction?

Hydraulic winches play a crucial role in heavy-duty applications like towing and construction, offering several advantages that contribute to their effectiveness in these industries:

- 1. High Load Capacity: Hydraulic winches are known for their high load capacity, making them well-suited for heavy-duty tasks. They can handle substantial loads, such as large construction equipment, vehicles, or materials, with ease.

- 2. Precise Load Control: In towing and construction, precision is vital. Hydraulic winches provide precise control over load movement, allowing operators to position heavy objects accurately and safely. This level of control is essential when maneuvering equipment or securing loads.

- 3. Variable Line Speed: Hydraulic winches offer variable line speed control, which is beneficial in heavy-duty applications. Operators can adjust the winch’s speed to match the specific requirements of the task, whether it’s slow and controlled movement or rapid retrieval.

- 4. Durability and Reliability: Heavy-duty environments demand equipment that can withstand harsh conditions. Hydraulic winches are designed for durability and reliability, making them dependable in rugged construction sites or challenging towing situations.

- 5. Overload Protection: Many hydraulic winches feature overload protection mechanisms. This safety feature prevents the winch from exerting excessive force, reducing the risk of equipment damage or accidents in towing and construction scenarios.

- 6. Adaptability to Different Vehicles: Hydraulic winches can be mounted on various types of vehicles, including tow trucks, construction machinery, and off-road vehicles. Their versatility ensures they can be used in a wide range of heavy-duty applications.

- 7. Remote Control: Remote control options allow operators to control hydraulic winches from a safe distance, increasing operator safety during heavy lifting or towing tasks.

- 8. Smooth Operation: Hydraulic winches provide smooth and consistent operation, reducing the risk of shock loading. This is critical when moving heavy loads or towing vehicles to prevent sudden jolts or equipment stress.

- 9. Adaptability to Environmental Conditions: Hydraulic winches can be equipped with features like special seals or temperature control mechanisms to operate effectively in extreme weather conditions or corrosive environments, which are common in construction and towing applications.

Overall, hydraulic winches are indispensable tools in heavy-duty applications like towing and construction, where their high load capacity, precision, durability, and safety features contribute to efficient and reliable operations.

What maintenance practices are recommended for hydraulic winches to ensure optimal functionality?

Proper maintenance of hydraulic winches is essential to ensure their optimal functionality, extend their service life, and enhance safety. Here are recommended maintenance practices for hydraulic winches:

- 1. Regular Inspection: Conduct routine visual inspections of the winch, including all components, hoses, and fittings. Look for signs of wear, leaks, corrosion, or damage. Inspect the winch drum, cable, and control mechanisms for any issues.

- 2. Lubrication: Ensure that all moving parts are adequately lubricated. Pay special attention to bearings, gears, and pivot points. Lubrication reduces friction, minimizes wear, and ensures smooth operation. Use the recommended lubricants specified by the manufacturer.

- 3. Hydraulic Fluid Checks: Monitor the hydraulic fluid level and condition regularly. Check for leaks in the hydraulic lines and fittings. Maintain the proper hydraulic fluid level and replace or top up fluid as needed with the correct type recommended by the manufacturer.

- 4. Control System Inspection: Examine the winch’s control system, including buttons, switches, and joysticks. Ensure that they function correctly and respond to commands promptly. Clean control surfaces to prevent dirt or debris from interfering with operation.

- 5. Cable Inspection: Inspect the winch cable or rope for signs of wear, fraying, or damage. Replace cables that show wear or damage to prevent accidents during operation. Ensure proper winding on the drum to avoid cable overlap or uneven spooling.

- 6. Brake System Check: If the winch is equipped with a brake system, verify that it engages and disengages properly. The brake system is critical for load control and safety during winching operations.

- 7. Fastener Tightening: Periodically check and tighten all fasteners, bolts, nuts, and hose clamps. Loose fasteners can lead to component failure or hydraulic fluid leaks.

- 8. Filter Maintenance: If the winch has hydraulic filters, follow the manufacturer’s guidelines for filter replacement or cleaning. Clean or replace filters regularly to prevent contamination of the hydraulic system.

- 9. Seal Inspection: Examine hydraulic seals for signs of wear or leaks. Damaged seals can lead to hydraulic fluid leaks and reduced winch performance. Replace seals as needed.

- 10. Electrical System Inspection: If the winch has electrical components, inspect wiring, connectors, and electrical connections for damage or corrosion. Ensure that the electrical system is in good working condition.

- 11. Operator Training: Ensure that operators are properly trained in the use of hydraulic winches. Adequate training can prevent misuse and accidents that may lead to equipment damage or injuries.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their winches, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Professional Service: Consider having the winch professionally inspected and serviced periodically. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, hydraulic winches can operate optimally, promoting safety, reliability, and longevity in various industries and applications.

What are hydraulic winches, and how do they differ from other types of winches?

Hydraulic winches are a type of winching equipment that utilizes hydraulic power to perform pulling or lifting tasks. They differ from other types of winches, such as electric or manual winches, in several ways:

- 1. Power Source: Hydraulic winches are powered by hydraulic systems, typically driven by a hydraulic pump connected to an external power source like an engine or a hydraulic power unit (HPU). In contrast, electric winches rely on electrical power, and manual winches are operated by hand.

- 2. Strength and Load Capacity: Hydraulic winches are known for their high strength and load capacity. They can handle extremely heavy loads and are often used in heavy-duty applications like construction, towing, and industrial operations. Electric winches, while capable, may have lower load capacities in comparison.

- 3. Continuous Operation: Hydraulic winches can operate continuously without overheating or the need for cooldown periods. This continuous-duty capability makes them suitable for long-duration tasks. Electric winches may require intermittent operation to prevent overheating.

- 4. Precision Control: Hydraulic winches offer precise control over pulling or lifting operations. Operators can control the speed and force of the winch through hydraulic valves, allowing for smooth and accurate movements. Manual winches lack this level of precision.

- 5. Durability and Reliability: Hydraulic winches are known for their durability and reliability in harsh environments. They are less susceptible to damage from exposure to elements like dust, water, and extreme temperatures. Electric winches may require additional protective measures.

- 6. Maintenance Requirements: Hydraulic winches have relatively low maintenance requirements, primarily consisting of routine hydraulic system maintenance. Electric winches may require more frequent maintenance of electrical components and wiring.

- 7. Cost: Hydraulic winches are often more expensive than their electric counterparts due to the complexity of hydraulic systems and the higher load capacities they offer. Manual winches are typically the most cost-effective option but have limited capacity.

- 8. Weight: Hydraulic winches tend to be heavier than electric winches, which can impact the choice of equipment and vehicle configurations. Electric winches are more lightweight and easier to install.

- 9. Noise Levels: Hydraulic winches can be quieter in operation compared to electric winches, making them suitable for applications where noise reduction is important.

In summary, hydraulic winches differ from other types of winches in terms of their power source, strength, continuous operation capability, precision control, durability, maintenance requirements, cost, weight, and noise levels. They are particularly well-suited for heavy-duty and demanding applications that require high load capacity and reliability.

editor by Dream 2024-05-16

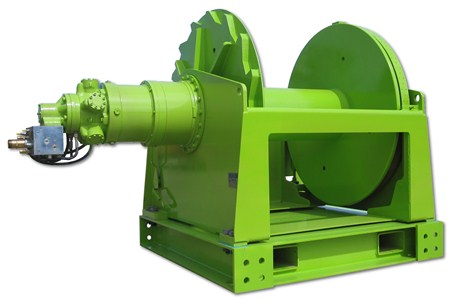

China OEM High Speed 0.2t 0.5t 0.8t Compact Lifting Hydraulic Winch for Small Equipment

Product Description

Parameter:

| Model | QLW120 |

| Single Line Pull | 2) |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Support |

|---|---|

| Warranty: | One Year |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | Fast |

| Carrying Capacity: | Middle-Level |

| Samples: |

US$ 400/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic winches contribute to heavy-duty applications such as towing or construction?

Hydraulic winches play a crucial role in heavy-duty applications like towing and construction, offering several advantages that contribute to their effectiveness in these industries:

- 1. High Load Capacity: Hydraulic winches are known for their high load capacity, making them well-suited for heavy-duty tasks. They can handle substantial loads, such as large construction equipment, vehicles, or materials, with ease.

- 2. Precise Load Control: In towing and construction, precision is vital. Hydraulic winches provide precise control over load movement, allowing operators to position heavy objects accurately and safely. This level of control is essential when maneuvering equipment or securing loads.

- 3. Variable Line Speed: Hydraulic winches offer variable line speed control, which is beneficial in heavy-duty applications. Operators can adjust the winch’s speed to match the specific requirements of the task, whether it’s slow and controlled movement or rapid retrieval.

- 4. Durability and Reliability: Heavy-duty environments demand equipment that can withstand harsh conditions. Hydraulic winches are designed for durability and reliability, making them dependable in rugged construction sites or challenging towing situations.

- 5. Overload Protection: Many hydraulic winches feature overload protection mechanisms. This safety feature prevents the winch from exerting excessive force, reducing the risk of equipment damage or accidents in towing and construction scenarios.

- 6. Adaptability to Different Vehicles: Hydraulic winches can be mounted on various types of vehicles, including tow trucks, construction machinery, and off-road vehicles. Their versatility ensures they can be used in a wide range of heavy-duty applications.

- 7. Remote Control: Remote control options allow operators to control hydraulic winches from a safe distance, increasing operator safety during heavy lifting or towing tasks.

- 8. Smooth Operation: Hydraulic winches provide smooth and consistent operation, reducing the risk of shock loading. This is critical when moving heavy loads or towing vehicles to prevent sudden jolts or equipment stress.

- 9. Adaptability to Environmental Conditions: Hydraulic winches can be equipped with features like special seals or temperature control mechanisms to operate effectively in extreme weather conditions or corrosive environments, which are common in construction and towing applications.

Overall, hydraulic winches are indispensable tools in heavy-duty applications like towing and construction, where their high load capacity, precision, durability, and safety features contribute to efficient and reliable operations.

Can you provide examples of industries or machinery that commonly use hydraulic winches?

Hydraulic winches find extensive use in various industries and are employed in a wide range of machinery and equipment. Here are examples of industries and machinery that commonly use hydraulic winches:

- 1. Construction: Hydraulic winches are integral in construction equipment such as cranes, excavators, and bulldozers for tasks like lifting heavy materials, positioning components, and anchoring loads.

- 2. Marine and Offshore: Ships and offshore platforms use hydraulic winches for anchor handling, mooring, towing, and launching lifeboats. They are essential for maritime operations.

- 3. Mining: In mining operations, hydraulic winches are used for ore extraction, moving heavy machinery, and managing conveyor systems. They play a vital role in the mining industry’s productivity.

- 4. Forestry: Logging equipment, including skidders and forwarders, rely on hydraulic winches for dragging logs and controlling felling operations in rugged forest terrain.

- 5. Oil and Gas: Hydraulic winches are used in drilling rigs, oil exploration, and offshore platforms for lifting and positioning equipment and handling drilling operations.

- 6. Recovery and Towing: Tow trucks and recovery vehicles use hydraulic winches to pull and recover vehicles stuck in various situations, providing roadside assistance and recovery services.

- 7. Agriculture: Agricultural machinery, such as tractors and combine harvesters, may use hydraulic winches for tasks like lifting implements or assisting in heavy-duty agricultural operations.

- 8. Off-Road and 4×4 Vehicles: Off-road enthusiasts and utility vehicles often feature hydraulic winches on their front bumpers to assist in self-recovery and assisting other vehicles in challenging terrain.

- 9. Industrial Manufacturing: Manufacturing facilities utilize hydraulic winches for material handling, moving heavy equipment, and controlling production processes.

- 10. Utilities: Utility trucks, including bucket trucks and digger derricks, use hydraulic winches for lifting personnel and equipment for maintenance and repairs on utility lines and infrastructure.

- 11. Agriculture: Agricultural machinery, such as tractors and combine harvesters, may use hydraulic winches for tasks like lifting implements or assisting in heavy-duty agricultural operations.

- 12. Military and Defense: Military vehicles and equipment employ hydraulic winches for recovery, logistics, and field operations, ensuring mission success in challenging conditions.

These examples illustrate the versatility and importance of hydraulic winches across various industries and applications, where their ability to provide controlled, high-force movement is crucial.

What are hydraulic winches, and how do they differ from other types of winches?

Hydraulic winches are a type of winching equipment that utilizes hydraulic power to perform pulling or lifting tasks. They differ from other types of winches, such as electric or manual winches, in several ways:

- 1. Power Source: Hydraulic winches are powered by hydraulic systems, typically driven by a hydraulic pump connected to an external power source like an engine or a hydraulic power unit (HPU). In contrast, electric winches rely on electrical power, and manual winches are operated by hand.

- 2. Strength and Load Capacity: Hydraulic winches are known for their high strength and load capacity. They can handle extremely heavy loads and are often used in heavy-duty applications like construction, towing, and industrial operations. Electric winches, while capable, may have lower load capacities in comparison.

- 3. Continuous Operation: Hydraulic winches can operate continuously without overheating or the need for cooldown periods. This continuous-duty capability makes them suitable for long-duration tasks. Electric winches may require intermittent operation to prevent overheating.

- 4. Precision Control: Hydraulic winches offer precise control over pulling or lifting operations. Operators can control the speed and force of the winch through hydraulic valves, allowing for smooth and accurate movements. Manual winches lack this level of precision.

- 5. Durability and Reliability: Hydraulic winches are known for their durability and reliability in harsh environments. They are less susceptible to damage from exposure to elements like dust, water, and extreme temperatures. Electric winches may require additional protective measures.

- 6. Maintenance Requirements: Hydraulic winches have relatively low maintenance requirements, primarily consisting of routine hydraulic system maintenance. Electric winches may require more frequent maintenance of electrical components and wiring.

- 7. Cost: Hydraulic winches are often more expensive than their electric counterparts due to the complexity of hydraulic systems and the higher load capacities they offer. Manual winches are typically the most cost-effective option but have limited capacity.

- 8. Weight: Hydraulic winches tend to be heavier than electric winches, which can impact the choice of equipment and vehicle configurations. Electric winches are more lightweight and easier to install.

- 9. Noise Levels: Hydraulic winches can be quieter in operation compared to electric winches, making them suitable for applications where noise reduction is important.

In summary, hydraulic winches differ from other types of winches in terms of their power source, strength, continuous operation capability, precision control, durability, maintenance requirements, cost, weight, and noise levels. They are particularly well-suited for heavy-duty and demanding applications that require high load capacity and reliability.

editor by Dream 2024-04-23

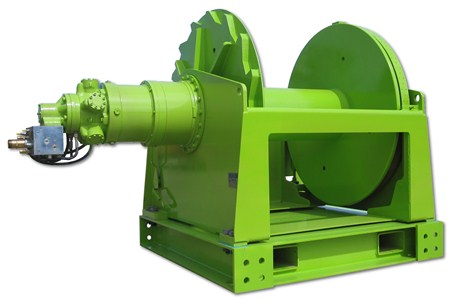

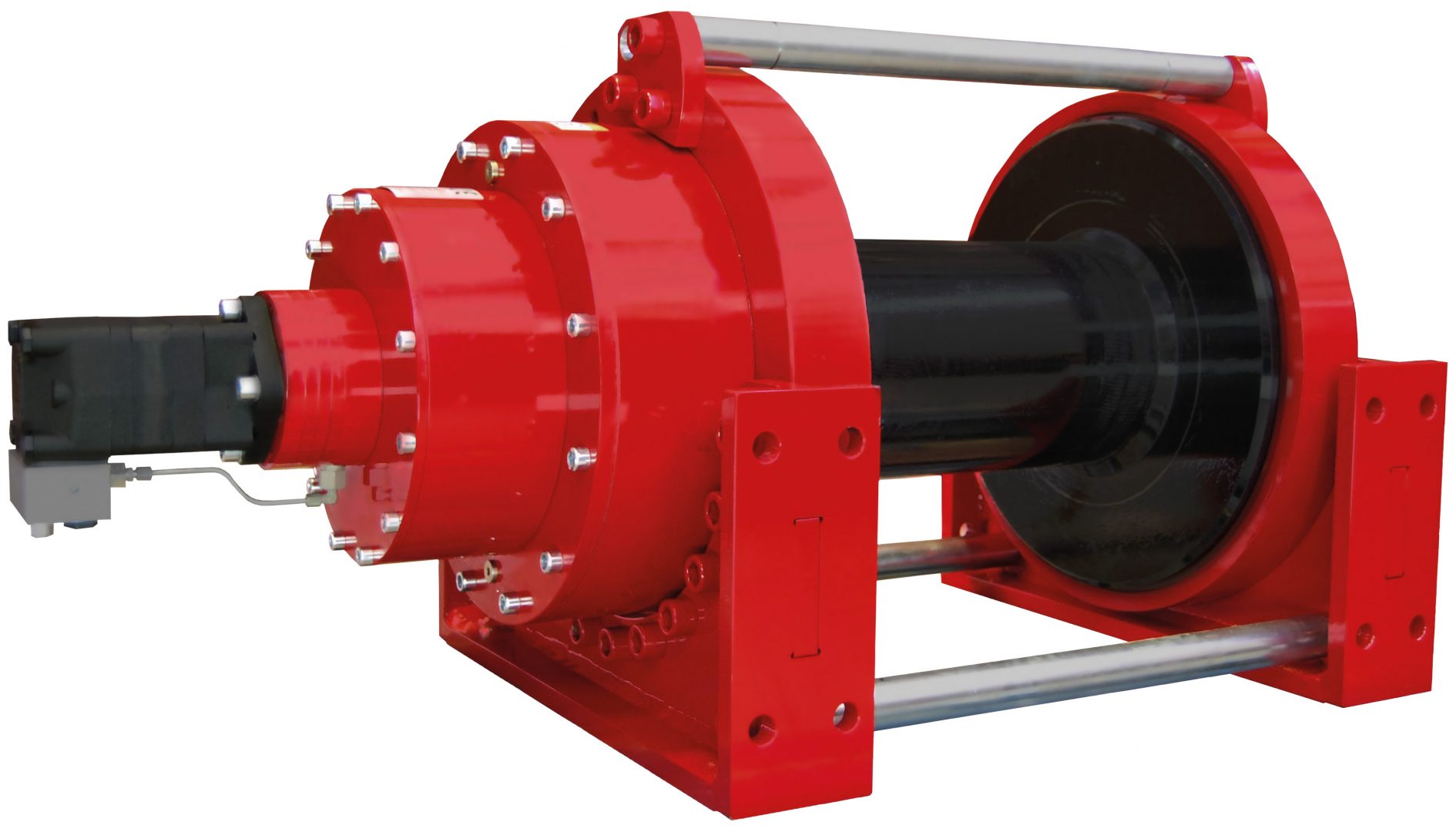

China Custom Lifting Equipment 10ton 20 Ton 30 Ton 50 Ton Towing Truck/ Wrecker /Drilling Rig/Aerial Platform/Crane/Boat Hydraulic Hoiting Pulling Winch of Sale

Product Description

Product Description

Lifting Equipment 10ton 20 Ton 30 Ton 50 Ton Towing Truck/ Wrecker /Drilling Rig/Aerial Platform/Crane/Boat Hydraulic Hoiting Pulling Winch of Sale

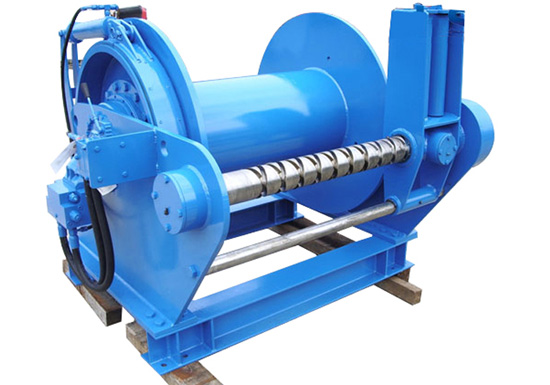

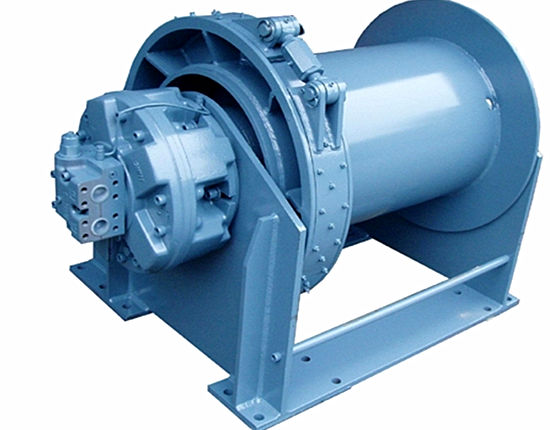

Hydraulic winch usually consists of a hydraulic motor, the control valve group, gear box, a roller, a bracket (clutch), rope pressing device or rope device, installation bracket combination and. Can be widely used in conveyor tensioning device and mechanical engineering from heavy machinery such as truck crane, crawler crane, aerial vehicles, forestry crane, and shipping

ports such as port cranes, floating crane, dredger, cranes, davits, and can for large play equipment such as oil rigs and offshore oil drilling platform, piling machinery rotary drilling rig, drilling, core drilling, hydrostatic pressure pile machine and so on.

| PRODUCTS NAME | Hydraulic Capstan Winch |

| Winches CAPAXIHU (WEST LAKE) DIS.TY | 1-100ton or customized according customer’s request |

| Winches USAGE | Lifting and pulling |

| PACKAGE | Standard woodden case or according customer’s request |

| OEM ODM SAMPLE | OK |

| APPLICATION | widely used in railway locomotives and automobile cranes, ships, oil field drilling and mining, coal mines, ports, small-scale construction machinery and other lifting traction equipment |

Detailed Photos

Packaging & Shipping

Hydraulic winch use Standard packing (Wooden case) or Customized packaging according to customer needs to better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Product Application

Hydraulic winch Application: Widely used in construction, water conservancy engineering, forestry, mining, wharf, etc. material lifting, such crane ,trailer ,truck ,wrecker ,etc also can be used as a modern electronic control automatic operation line supporting.

Main Products

Hydraulic Winches Hoistting Winches Electric Winches

Slewing Drive Reducer Final Drive Reducer Hydraulic Motor

Our Company

Taian Chuangdong New Material Technology Co., Ltd. is located in CHINAMFG City, ZheJiang Province, China. The factory was established in 2008 and specializes in the research and development of planetary transmission technology products. The factory has completeequipment and strong processing capabilities, including boring machines, machining centers, gear shapers, CNC lathes, drilling machines, and other processing equipment. In addition, the inspection and testing equipment is complete, with main inspection methods such as metallographic and physicochemical examination, gear inspection, and finished product loading experiments. The factory has successively developed a series of planetary transmission mechanisms in the fields of lifting machinery, exploration machinery, obstacle clearance machinery, aerial work vehicle machinery , marine machinery, petroleum machinery, and truck mounted cranes. At present, our company main products include 8-100 ton hoisting and slewing mechanisms for truck cranes,16-100 ton walking mechanisms for crawler cranes, 18-30 meter hoisting and slewing mechanisms for aerial work vehicles, 6-25 ton hydraulic winches and slewing mechanisms for truck mounted cranes, and 1.5-30 ton IYJ series hydraulic winches widely used in obstacle clearing machinery, marine machinery, and petroleum machinery. The company actively cooperates with various main engine

manufacturers to develop products, and also cooperates with ZheJiang Machinery Design Institute, ZheJiang University, HangZhou University of Technology and other universities to develop a series of refined and new products, which have won recognition from the vast market.

In recent years, with the development and growth of domestic construction machinery, the company has closely followed the market situation, vigorously invested in equipment, built standardized factories, and continuously expanded and strengthened the company scale.

We welcome your cooperation.

FAQ

Q: Are you trading company or manufacturer ?

A: We are professional factory.

Q: What is your terms of payment?

A: T/T and 100% Irrevocable LC

Q: What is your terms of delivery?

A: FOB, CFR ,CIF, DDU or as your requirement.

Q:Do you supply customized service?

A: Sure! We are manufacturer, and we have our own engineer group. They can work out customized design according to your special requirement.

Q: How about your delivery time? A: Generally it will take 7-35 days after receiving your advance payment .The specific delivery time depends on your purchase quantity.

Q: How about package? A: Wooden box conforming to export standards.

Q:What information should I provide to you before you could recommend a suitable winch and quote for me?

A: 1. Intended application of the winch (including working condition)

2. Line pull (KN / kgs / lbs)

3. Line speed (m/min)

4. Drum capacity/rope length (m)

5. Rope diameter(if have)

6. Oil pressure and oil flow (if have)

7. Other special requirements We will always be your service, welcome for your enquiry!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Can Be Consulted |

|---|---|

| Warranty: | 1-3 Years |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | Fast |

| Carrying Capacity: | Light and Weight and Middle and Special |

| Samples: |

US$ 1500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you share tips for selecting the right hydraulic winch based on specific industry requirements and load capacities?

Selecting the right hydraulic winch based on industry requirements and load capacities involves careful consideration of various factors. Here are some tips to help you make an informed choice:

- 1. Determine Load Capacity: Start by assessing the maximum load capacity you need. Consider both the weight of the load and any additional factors like incline or resistance. Choose a winch with a rated capacity that exceeds your requirements to ensure safety and performance.

- 2. Evaluate Line Speed: Different winches offer varying line speeds. Determine the optimal line speed for your application. For precision and control, slower speeds may be suitable, while faster speeds are ideal for rapid retrieval. Ensure the winch you select has the appropriate speed range.

- 3. Consider Duty Cycle: Some winches are designed for intermittent use, while others are built for continuous duty. Evaluate your application’s duty cycle to choose a winch that can handle the expected workload without overheating or excessive wear.

- 4. Assess Environmental Conditions: Take into account the environmental conditions in which the winch will operate. Extreme temperatures, moisture, or corrosive environments may require special seals or coatings for durability. Ensure the winch can withstand the intended environment.

- 5. Review Safety Features: Safety is paramount. Look for winches with safety features such as overload protection, emergency stop mechanisms, and load-holding capabilities. These features enhance safety during winching operations.

- 6. Check Compatibility: Ensure that the chosen hydraulic winch is compatible with the equipment or vehicle it will be mounted on. Compatibility issues can lead to operational problems and reduced reliability.

- 7. Evaluate Control Systems: Consider whether you need advanced control features. Modern hydraulic winches often feature electronic control systems that offer precise control and safety enhancements. Determine if these features are beneficial for your application.

- 8. Review Maintenance Requirements: Assess the ease of maintenance and the availability of replacement parts. Winches with accessible components and manufacturer support are preferable for long-term reliability.

- 9. Consult with Experts: If you’re uncertain about the right winch for your application, consult with industry experts or the manufacturer. They can provide valuable insights and recommendations based on their experience and expertise.

- 10. Consider Future Needs: Anticipate potential changes or future requirements in your industry. Select a winch that can adapt to evolving needs, ensuring a longer lifespan for your investment.

By carefully considering these tips and tailoring your choice to your specific industry requirements and load capacities, you can select the right hydraulic winch that will deliver reliable performance and meet your operational needs.

What maintenance practices are recommended for hydraulic winches to ensure optimal functionality?

Proper maintenance of hydraulic winches is essential to ensure their optimal functionality, extend their service life, and enhance safety. Here are recommended maintenance practices for hydraulic winches:

- 1. Regular Inspection: Conduct routine visual inspections of the winch, including all components, hoses, and fittings. Look for signs of wear, leaks, corrosion, or damage. Inspect the winch drum, cable, and control mechanisms for any issues.

- 2. Lubrication: Ensure that all moving parts are adequately lubricated. Pay special attention to bearings, gears, and pivot points. Lubrication reduces friction, minimizes wear, and ensures smooth operation. Use the recommended lubricants specified by the manufacturer.

- 3. Hydraulic Fluid Checks: Monitor the hydraulic fluid level and condition regularly. Check for leaks in the hydraulic lines and fittings. Maintain the proper hydraulic fluid level and replace or top up fluid as needed with the correct type recommended by the manufacturer.

- 4. Control System Inspection: Examine the winch’s control system, including buttons, switches, and joysticks. Ensure that they function correctly and respond to commands promptly. Clean control surfaces to prevent dirt or debris from interfering with operation.

- 5. Cable Inspection: Inspect the winch cable or rope for signs of wear, fraying, or damage. Replace cables that show wear or damage to prevent accidents during operation. Ensure proper winding on the drum to avoid cable overlap or uneven spooling.

- 6. Brake System Check: If the winch is equipped with a brake system, verify that it engages and disengages properly. The brake system is critical for load control and safety during winching operations.

- 7. Fastener Tightening: Periodically check and tighten all fasteners, bolts, nuts, and hose clamps. Loose fasteners can lead to component failure or hydraulic fluid leaks.

- 8. Filter Maintenance: If the winch has hydraulic filters, follow the manufacturer’s guidelines for filter replacement or cleaning. Clean or replace filters regularly to prevent contamination of the hydraulic system.

- 9. Seal Inspection: Examine hydraulic seals for signs of wear or leaks. Damaged seals can lead to hydraulic fluid leaks and reduced winch performance. Replace seals as needed.

- 10. Electrical System Inspection: If the winch has electrical components, inspect wiring, connectors, and electrical connections for damage or corrosion. Ensure that the electrical system is in good working condition.

- 11. Operator Training: Ensure that operators are properly trained in the use of hydraulic winches. Adequate training can prevent misuse and accidents that may lead to equipment damage or injuries.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their winches, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Professional Service: Consider having the winch professionally inspected and serviced periodically. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, hydraulic winches can operate optimally, promoting safety, reliability, and longevity in various industries and applications.

Can you describe the factors to consider when selecting hydraulic winches for specific applications?

Selecting the right hydraulic winch for a specific application involves considering various factors to ensure optimal performance and safety. Here are key factors to take into account:

- 1. Load Capacity: Determine the maximum load the winch will need to handle. Choose a hydraulic winch with a capacity that comfortably exceeds the heaviest load you anticipate. Keep in mind that it’s safer to have a winch with a higher capacity than required.

- 2. Line Speed: Consider the speed at which you need to pull or lift the load. Hydraulic winches offer different line speeds, so choose one that aligns with your application’s requirements. Keep in mind that line speed may vary depending on the load.

- 3. Duty Cycle: Evaluate how frequently and for how long the winch will be in operation. Some winches are designed for continuous use, while others have intermittent duty cycles. Ensure the winch’s duty cycle matches the demands of your application.

- 4. Mounting and Installation: Assess the available space for mounting the winch and the compatibility of the winch’s mounting configuration with your equipment or vehicle. Consider the ease of installation and any additional mounting accessories required.

- 5. Control Options: Determine the level of control you need over the winch. Hydraulic winches may offer manual, remote, or integrated control options. Choose a control method that suits your operational preferences and safety requirements.

- 6. Environmental Conditions: Consider the environmental conditions in which the winch will operate. Hydraulic winches are suitable for various environments, but factors like temperature extremes, exposure to saltwater, and dust levels may influence your choice.

- 7. Safety Features: Check for safety features such as overload protection, emergency stop mechanisms, and fail-safe braking systems. These features enhance operator safety and protect against accidents.

- 8. Cable or Rope Type: Select the appropriate type of cable or rope for your application, considering factors like strength, durability, and compatibility with the winch drum. Ensure that the winch drum can accommodate the chosen cable or rope size.

- 9. Maintenance Requirements: Evaluate the maintenance needs of the hydraulic winch. Some models may require more frequent maintenance than others. Choose a winch that aligns with your maintenance schedule and capabilities.

- 10. Budget Considerations: Set a budget for the hydraulic winch purchase. While it’s essential to meet your application’s requirements, also consider the cost of the winch, installation, and any additional accessories or hydraulic system modifications.

- 11. Brand Reputation and Support: Research and select reputable brands with a history of manufacturing reliable hydraulic winches. Consider the availability of spare parts, technical support, and warranty coverage from the manufacturer.

- 12. Compliance with Standards: Ensure that the selected hydraulic winch complies with relevant industry standards and regulations. This is particularly important in safety-critical applications.

By carefully considering these factors, you can choose the right hydraulic winch that meets the specific requirements of your application, ensuring safe and efficient winching operations.

editor by CX 2024-04-13

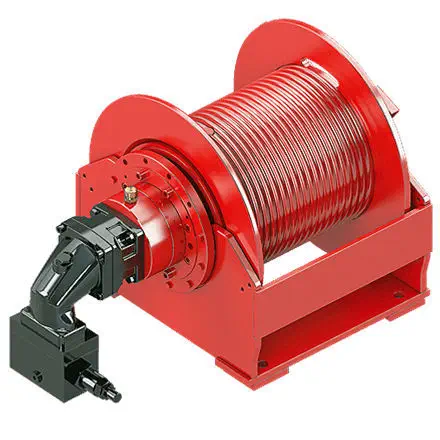

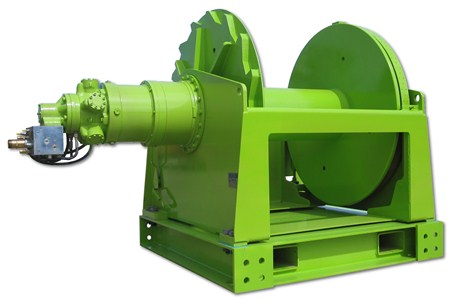

China Good quality Marine Boat Barge Equipment Electric Cable Drum Anchor Winch Windlass 3ton 10ton 20t 25ton 30ton 40t Ship Hydraulic Spooling Mooring Winch Price

Product Description

Product Description

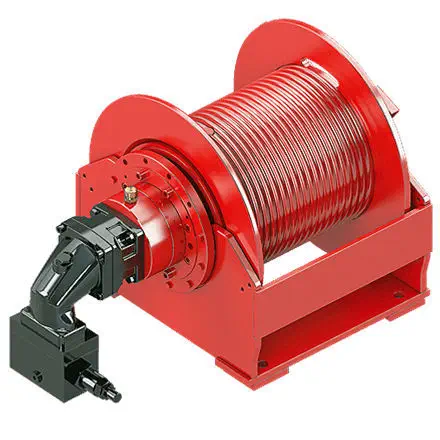

| Marine Boat Barge Equipment Electric Cable Drum Anchor Winch Windlass 3ton 10ton 20t 25ton 30ton 40t Ship Hydraulic Spooling Mooring Winch Price |

Multipurpose. Lifting, supporting and hauling goods with hand-driver.

Safety and reliability. Easy stop in any position with self-lock.

Lubrication. Factory lubrication before packaging.

Optional drums. Three options available: Single drum, split drum or widened drum.

Serial model. Suit with different rated load.

Super performance. Cast worm with heat-treated gear makes the mechanism unique reliable and durable.

Smooth drive. Oil-retaining bushings or bearing for smooth drive.

Durable surface finish. Powder-coated surface plus zinc-plating for longer corrosion resistance.

Manual Winch:

Hydraulic Winch:

Electric Winch:

Anchor Winch:

Towing Mooring Hook:

Packaging & Shipping

Customer Visit

Company Profile

ZheJiang CHINAMFG Machinery Equipment, established in 1998, is a one-stop solution supplier engaged in the research, development, sale and service of all kinds of marine equipments, hydraulic winches, electric winches, diesel engine power winches, anchor winches, mooring winches,marine ship crane, port crane, towing mooring hook, boat anchor, electric grab, hydraulic grab, and so on. We have obtained many certificates, like BV, CCS, NK, RMRS etc. Because of high quality products, competitive prices and excellent services, our products sell well all over the world, like USA, UK, UAE, Germany, France, Italy, Kenya, Uganda, Ghana, Bangladesh, India, Philippines, Malaysia, Russia and many other countries. There are some professional technical engineers in our team, OEM and ODM orders are available. If you have any new ideas or concepts for the products, Welcome to contact us any time.

FAQ

Q 1:What kinds of payment terms can you accept?

We have many payment methods to meet different customer request, such as T/T, Western Union, L/C. If your bank has other solutions, We can talk later, it is not a problem for our business.

Q 2: What trade terms can you accept?

We normally trade with our customers in EX-Works, FOB, CFR and CIF. Delivery ports can be HangZhou, ZheJiang , ZheJiang , HangZhou, HangZhou.

Q 3: How about the lead time?

30 to 60 working days after down payment.

Q 4: How about the transportation?

Because of heavy weight and big sizes, we usually deliver equipments by sea, which is much cheaper than by train and by Air. It also depends on clients’ decisions. We will try our best to help you

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Video Support |

|---|---|

| Warranty: | 1year |

| Type: | Hydraulic Winch |

| Samples: |

US$ 5000/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the impact of hydraulic winches on the overall safety of lifting and pulling tasks?

Hydraulic winches significantly impact the overall safety of lifting and pulling tasks across various industries. Their design and features contribute to enhanced safety in the following ways:

- 1. Precise Control: Hydraulic winches provide operators with precise control over load movement. The ability to vary line speed and direction accurately ensures that loads can be positioned and moved safely without abrupt or unpredictable movements.

- 2. Variable Line Speed: Hydraulic winches offer variable line speed control, allowing operators to adjust the speed according to the task’s requirements. This adaptability is crucial for safely handling different loads and situations, preventing sudden jolts or over-speeding.

- 3. Overload Protection: Many hydraulic winches are equipped with overload protection mechanisms. These features prevent the winch from exerting excessive force beyond its capacity, reducing the risk of equipment damage or failure. Overload protection ensures safe operation even when loads unexpectedly become too heavy.

- 4. Smooth Operation: Hydraulic systems provide smooth and consistent operation, minimizing jerky movements or sudden stops. This reduces the risk of shock-loading, which can lead to equipment stress and load instability, posing safety hazards.

- 5. High Force Output: Hydraulic winches generate high torque and force, allowing them to handle heavy loads efficiently. This high force capability ensures that loads can be controlled and moved safely, even in challenging conditions.

- 6. Consistent Performance: Hydraulic systems maintain a constant force output regardless of load variations. This consistency ensures that the winch performs predictably and safely, reducing the likelihood of accidents due to unexpected changes in load force.

- 7. Operator Safety: The ability to control hydraulic winches remotely or from a safe distance enhances operator safety. Operators can maintain a safe distance from the load, reducing the risk of injury in case of unexpected load movement.

- 8. Durability: Hydraulic winches are known for their durability and resistance to wear and tear. Properly maintained hydraulic systems have a longer service life, reducing the need for frequent replacements and associated risks during installation or maintenance.

- 9. Adaptability to Environmental Conditions: Hydraulic winches can be customized with features such as special seals, coolers, or heaters to adapt to various environmental conditions. This ensures that the winch functions safely and reliably in extreme temperatures or corrosive environments.

- 10. Operator Training: Adequate operator training is crucial for safe winch operation. Training ensures that operators understand the winch’s capabilities and limitations, as well as safety procedures, preventing accidents caused by misuse.

Overall, hydraulic winches provide a level of safety that is critical in industries where lifting and pulling tasks involve heavy loads, precise positioning, and potentially hazardous environments. Their ability to offer controlled, high-force movements enhances safety for both operators and equipment.

How does the hydraulic system impact the overall efficiency and reliability of winching operations?

The hydraulic system plays a significant role in enhancing the efficiency and reliability of winching operations. Its impact is substantial, making hydraulic winches preferred choices in various applications. Here’s how the hydraulic system contributes to overall efficiency and reliability:

- 1. High Force Output: Hydraulic winches can generate high force, thanks to the hydraulic fluid’s incompressible nature. This high force allows them to handle heavy loads efficiently and overcome resistance, making them reliable for challenging tasks.

- 2. Precise Control: Hydraulic systems provide precise control over winching operations. Operators can finely adjust the speed and direction of movement, allowing for accurate positioning and controlled lifting or pulling. This precision minimizes the risk of accidents and damage to equipment or loads.

- 3. Consistent Performance: Hydraulic systems offer consistent performance, regardless of load variations. The hydraulic pump maintains a constant flow of fluid, ensuring that the winch operates at a consistent speed and force. This consistency is crucial for reliable and predictable operations.

- 4. Variable Line Speed: Hydraulic winches offer variable line speed control. By adjusting the flow rate of hydraulic fluid, operators can vary the winch’s speed to match specific requirements. This adaptability improves efficiency in tasks with varying speed demands.

- 5. Overload Protection: Many hydraulic winches are equipped with overload protection mechanisms. These safety features prevent the winch from exerting excessive force beyond its capacity, reducing the risk of equipment damage or failure. Overload protection enhances the reliability of winching operations.

- 6. Durability and Longevity: Hydraulic systems are known for their durability and longevity. They can withstand heavy use and harsh environmental conditions. Properly maintained hydraulic winches can have a long service life, reducing downtime and replacement costs.

- 7. Low Heat Buildup: Hydraulic systems produce less heat during operation compared to electric winches. Lower heat buildup reduces the risk of overheating and extends the life of hydraulic components, contributing to reliability.

- 8. Adaptability to Environmental Conditions: Hydraulic winches can be adapted to various environmental conditions. Special seals, coolers, or heaters can be added to ensure proper hydraulic fluid temperature regulation, making them reliable in extreme temperatures or corrosive environments.

- 9. Reduced Shock Loading: The smooth and controlled operation of hydraulic winches minimizes shock loading, which occurs when a load is suddenly jerked or stopped. This reduces stress on equipment and loads, contributing to overall reliability.

In summary, the hydraulic system’s ability to provide high force, precise control, and consistent performance enhances the efficiency and reliability of winching operations across a wide range of industries and applications.

Can you describe the factors to consider when selecting hydraulic winches for specific applications?

Selecting the right hydraulic winch for a specific application involves considering various factors to ensure optimal performance and safety. Here are key factors to take into account:

- 1. Load Capacity: Determine the maximum load the winch will need to handle. Choose a hydraulic winch with a capacity that comfortably exceeds the heaviest load you anticipate. Keep in mind that it’s safer to have a winch with a higher capacity than required.

- 2. Line Speed: Consider the speed at which you need to pull or lift the load. Hydraulic winches offer different line speeds, so choose one that aligns with your application’s requirements. Keep in mind that line speed may vary depending on the load.

- 3. Duty Cycle: Evaluate how frequently and for how long the winch will be in operation. Some winches are designed for continuous use, while others have intermittent duty cycles. Ensure the winch’s duty cycle matches the demands of your application.

- 4. Mounting and Installation: Assess the available space for mounting the winch and the compatibility of the winch’s mounting configuration with your equipment or vehicle. Consider the ease of installation and any additional mounting accessories required.

- 5. Control Options: Determine the level of control you need over the winch. Hydraulic winches may offer manual, remote, or integrated control options. Choose a control method that suits your operational preferences and safety requirements.

- 6. Environmental Conditions: Consider the environmental conditions in which the winch will operate. Hydraulic winches are suitable for various environments, but factors like temperature extremes, exposure to saltwater, and dust levels may influence your choice.

- 7. Safety Features: Check for safety features such as overload protection, emergency stop mechanisms, and fail-safe braking systems. These features enhance operator safety and protect against accidents.

- 8. Cable or Rope Type: Select the appropriate type of cable or rope for your application, considering factors like strength, durability, and compatibility with the winch drum. Ensure that the winch drum can accommodate the chosen cable or rope size.

- 9. Maintenance Requirements: Evaluate the maintenance needs of the hydraulic winch. Some models may require more frequent maintenance than others. Choose a winch that aligns with your maintenance schedule and capabilities.

- 10. Budget Considerations: Set a budget for the hydraulic winch purchase. While it’s essential to meet your application’s requirements, also consider the cost of the winch, installation, and any additional accessories or hydraulic system modifications.

- 11. Brand Reputation and Support: Research and select reputable brands with a history of manufacturing reliable hydraulic winches. Consider the availability of spare parts, technical support, and warranty coverage from the manufacturer.

- 12. Compliance with Standards: Ensure that the selected hydraulic winch complies with relevant industry standards and regulations. This is particularly important in safety-critical applications.

By carefully considering these factors, you can choose the right hydraulic winch that meets the specific requirements of your application, ensuring safe and efficient winching operations.

editor by CX 2024-04-04

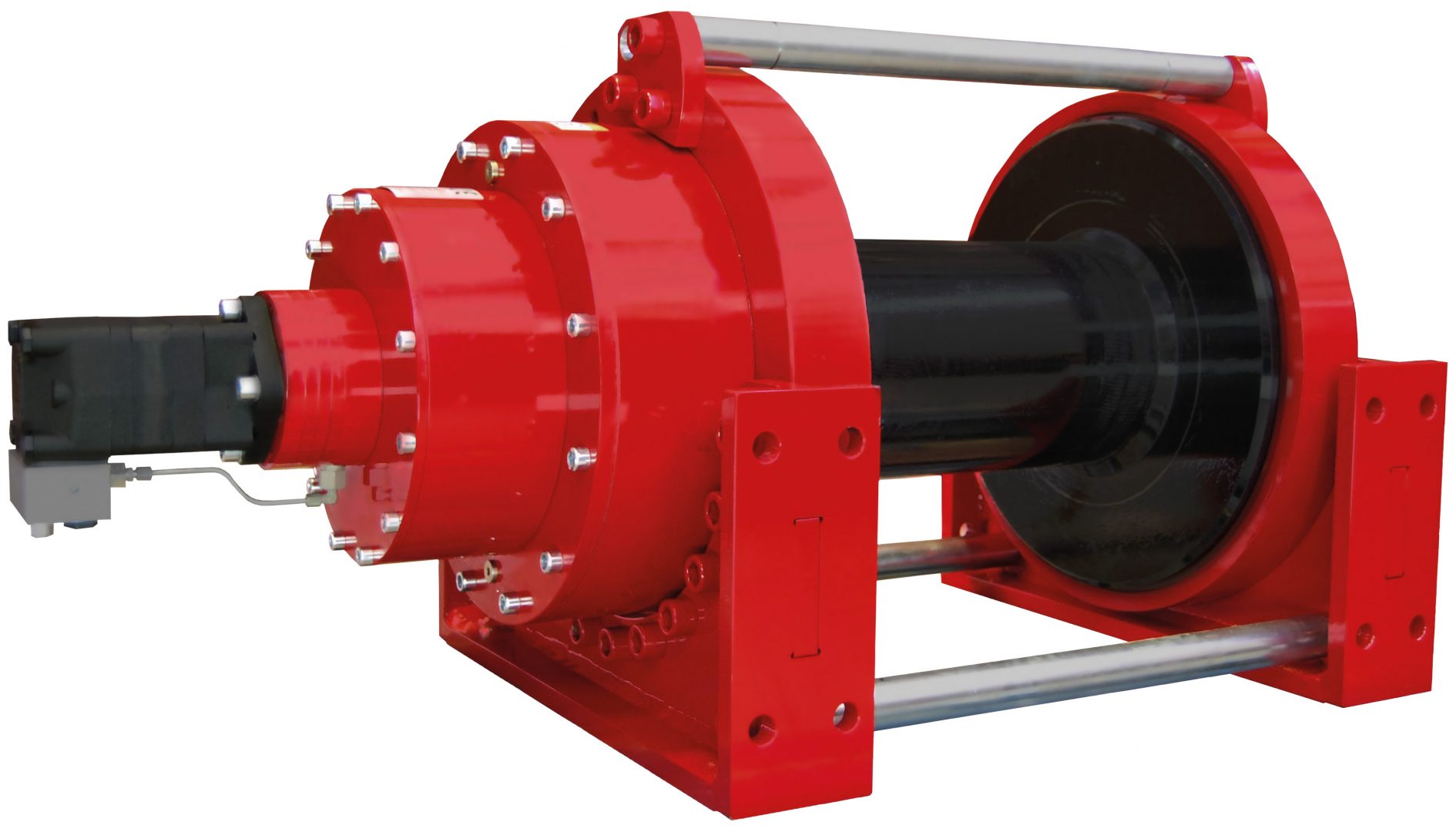

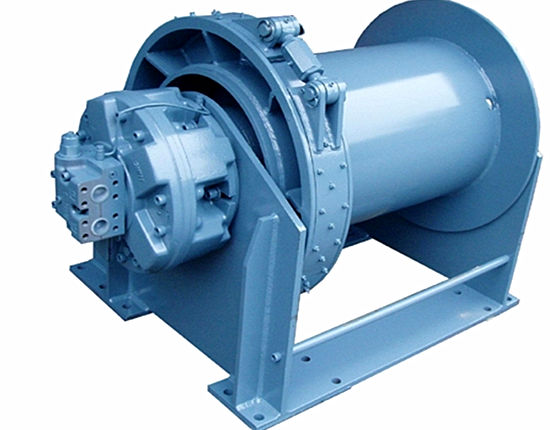

China wholesaler Lifting Equipment 5/10/30 Ton Marine Boat Crane Hydraulic Winch

Product Description

Product Description

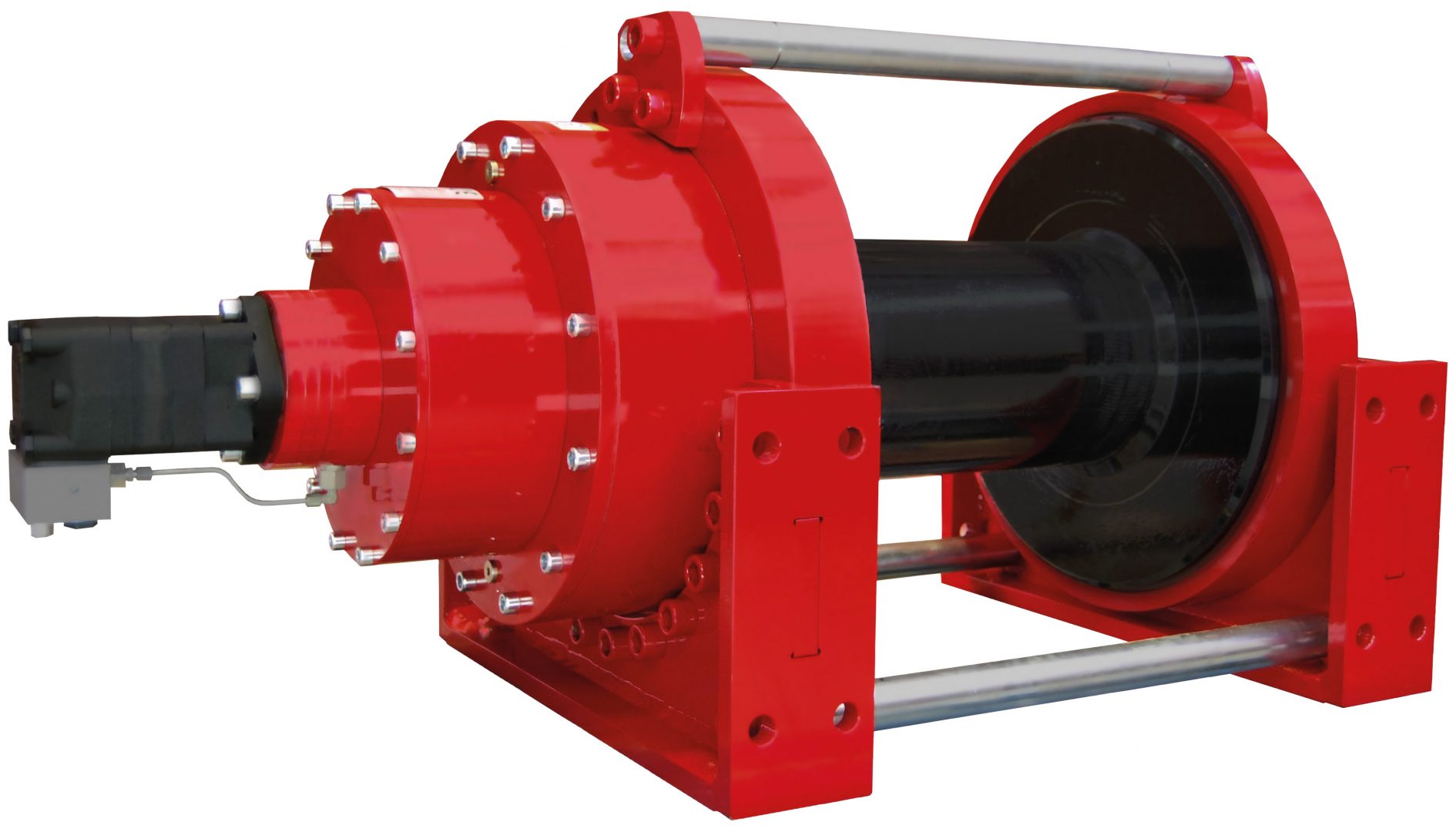

Peka hydraulic having more than 20 years production experience.Our winch can be used to replace the winch of Brevini and Dinamic.We can also customized accoding to customer’s requirement in order to well match the equipment.Our Hoisting Winches are patent products of our company and consist of a variety of distributors with shuttle valves

We are professional manufacturer for hydraulic products.Our products comply with CHINAMFG quality and safety standards.Our company is equipped with a test rack,each winch will be tested before delivery,ensure that every winch received by customer is in good working.

Hydraulic Winches working capacities from 11 lbs. (80000 kgs).Operate in lowest temperatures -60°C.

In addition, the winches can lift and put down stably,high efficiency,low energy consumption,low noise and beautiful form.Our Hydraulic winches have been well sold in China and also have been exported to England, the Middle-east, the south-east Asia, Korea and so on.

Detailed Photos

Good Price Other Winches High Speed Hydraulic Winch Cable Lifting Winch

Product Parameters

| Model | The 1st layer | Reel bottom diameter(mm) | Total displacement (ml/r) | Working pressure diff.(MPa) | Rope diameter (mm) | Wire rope Capacity(m) | Hydraulic motor | Model of planetary reducer | |

| Pull (kN) | Rope speed(m/min) | ||||||||

| GW2.5-10-60-10-ZP | 10 | 0-30 | 238 | 575 | 15 | 10 | 60 | GN05-110D51 | C2.5-5 |

| GW2.5-20-50-12-ZP | 20 | 0-30 | 238 | 1050 | 17 | 12 | 50 | GN05-200D51 | C2.5-5.5 |

| GW3-30-65-15-ZP | 30 | 0-35 | 305 | 2125 | 15.9 | 15 | 65 | GN2-420D51 | C3-5 |

| GW3-40-60-16-ZP | 40 | 0-35 | 305 | 2711.5 | 16.4 | 16 | 60 | GN2-500D51 | C3-5.5 |

| GW4-50-70-20-ZP | 50 | 0-40 | 380 | 4365 | 16.3 | 20 | 70 | GN3-900D245711 | C4-5 |

| GW4-60-68-21.5-ZP | 60 | 0-40 | 380 | 5428.5 | 16 | 21.5 | 68 | GN3-1000D245711 | C4-5.5 |

| GW5-80-100-24-ZP | 80 | 0-40 | 470 | 9080 | 15.6 | 24 | 100 | GN5-1800D245711 | C5-5 |

| GW5-100-90-28-ZP | 100 | 0-40 | 470 | 11039 | 16 | 28 | 90 | GN5-2000D245711 | C5-5.5 |

| GW7-180-143-38-ZF | 180 | 0-30 | 640 | 23639 | 17.8 | 38 | 143 | GNS7-4300D485711 | C7-5.5 |

| Model | The 1st layer | Total displacement (ml/r) | Working pressure diff.(MPa) | oil flow supply (L/min) | Rope diameter (mm) | Layer | Wire rope Capacity(m) | Hydraulic motor | Gearbox model (Ratio) | |

| Pull (kN) | Rope speed(m/min) | |||||||||

| PYJ22-10-86-8-ZPND | 10 | 40 | 480.9 | 16 | 36 | 8 | 6 | 86 | IM22 | KC22(i=21.86) |

| PYJ-ZPND | 15 | 40 | 568.4 | 21 | 43 | 10 | 5 | 55 | IM26 | |

| PYJ-ZPND | 20 | 40 | 644.9 | 24 | 49 | 10 | 5 | 55 | IM30 | |

| PYJ-ZPND | 25 | 40 | 762.9 | 25 | 57 | 12 | 4 | 38 | IM35 | |

| PYJ2.52.5-15-100-12-ZPNC | 15 | 40 | 986.5 | 15 | 60 | 12 | 5 | 100 | IM30 | KC2.52.5-B(i=32.45) |

| PYJ2.52.5-18-100-12-ZPNC | 18 | 40 | 17 | |||||||

| PYJ2.52.5-20-100-12-ZPNC | 20 | 40 | 19 | |||||||

| PYJ2.52.5-25-100-12-ZPNC | 25 | 40 | 24 | |||||||

| PYJ2.52.5-20-160-12-ZPND | 20 | 40 | 843.7 | 23 | 50 | 12 | 6 | 160 | IM26 | KC2.52.5-B(i=32.45) |

| PYJ2.52.5-25-160-12-ZPND | 25 | 35 | 986.5 | 24 | 52 | 12 | 6 | 160 | IM30 | |

| PYJ2.52.5-15-100-10-ZPNE | 15 | 40 | 986.5 | 15 | 60 | 10 | 5 | 100 | IM30 | KC2.52.5-B(i=32.45) |

| PYJ2.52.5-18-100-10-ZPNE | 18 | 40 | 17 | |||||||

| PYJ2.52.5-20-100-12-ZPNE | 20 | 40 | 19 | 12 | 4 | 90 | ||||

| PYJ2.52.5-25-100-12-ZPNE | 25 | 40 | 24 | |||||||

| PYJ-ZPNB | 40 | 25 | 40 | 80 | 2933.3 | 1864.8 | 200 | 124 | 16 | 4 |

| PYJ-ZPNB | 50 | 32 | 40 | 80 | 240 | |||||

| PYJ-ZPNB | 55 | 35 | 40 | 80 | 270 | |||||

| PYJ-ZPNB | 60 | 38 | 40 | 80 | 290 | |||||

Certifications

Packaging & Shipping

Company Profile

ZHangZhoug New CHINAMFG Hydraulic Co., Ltd. is a professional manufacturer of hydraulic winch/planetary reducers/gearbox. At present,we developed tens of thousands specifications of the hydraulic winch/planetary reducer/gearbox, travel drive,swing drive and winch drive.Working capacity for hydraulic winch is from 0.5-80T.The ratio range of planetary gearbox is 3.3~9000, and the output torque range is 500~1200000N.m. The installation, dimensions and performance parameters of the reducer are exactly the same as famous European brands, which can be perfectly replaced and interchanged.

Our Advantages

What We Can Do

1. One year warranty from delivery

2. Free components for replacement within warranty period

3. Professional solution provider

4. Free technical support at any time

5. Customer training is available.

6. On-site installation and commissioning is available.

7. Each winch will be tested before delivery

FAQ

Q1:What’s you MOQ?

A:MOQ is 1 piece.

Q2:What should I supply to get a suitable model of hydraulic winch and quotation?

A: In order to recommend a most suitable model of hydraulic winch we should to know:

1.Line pull(t)

2.Line Speed(m/min)

3.Drum capacity/Rope Length(m)

4.Rope Diameter(if have)

5.With braker or not

6.Which kind of machine does the hydraulic used on?

7.hydraulic system pressure and pump flow(if have)

8.other special requrements

| After-sales Service: | on Line |

|---|---|

| Warranty: | 1 Year |

| Type: | Construction Winch |

| Driven Type: | Hydraulic |

| Speed: | Slow |

| Carrying Capacity: | Middle-Level |

| Customization: |

Available

|

|

|---|

Can you provide insights into the importance of proper installation and maintenance of hydraulic winches?

Proper installation and maintenance of hydraulic winches are of paramount importance in ensuring their safe and reliable operation. Here are insights into why these practices are crucial:

- 1. Safety: Safety is a primary concern when it comes to hydraulic winches. Proper installation ensures that the winch is securely mounted and integrated into the equipment or vehicle. Regular maintenance helps identify and address any safety-related issues, such as worn components or hydraulic leaks.

- 2. Reliability: Hydraulic winches are often used in critical applications where reliability is essential. Correct installation by following manufacturer guidelines and routine maintenance procedures ensure that the winch performs as expected when needed. This reliability is particularly critical in industries like towing, construction, and offshore operations.

- 3. Longevity: Hydraulic winches are substantial investments, and proper installation and maintenance can significantly extend their lifespan. This reduces the need for premature replacements and associated costs, contributing to long-term cost-effectiveness.

- 4. Performance: Correct installation and regular maintenance are key to maintaining the winch’s performance. Lubricating moving parts, inspecting hydraulic components, and ensuring proper cable spooling all contribute to optimal winching performance.

- 5. Preventing Downtime: Unscheduled downtime can be costly in various industries. Routine maintenance helps detect and address issues before they lead to equipment failure. Preventive maintenance minimizes unexpected downtime and keeps operations running smoothly.

- 6. Avoiding Accidents: Properly installed and well-maintained hydraulic winches are less likely to malfunction or cause accidents. Malfunctions, such as cable snapping or hydraulic system failures, can lead to serious accidents and injuries. Following installation and maintenance procedures reduces these risks.

- 7. Compliance with Regulations: In some industries, compliance with safety regulations and standards is mandatory. Proper installation and maintenance help ensure that hydraulic winches meet these requirements, preventing regulatory issues and potential liabilities.

- 8. Resale Value: If the time comes to replace or upgrade hydraulic winches, well-maintained equipment has a higher resale value. Buyers are more inclined to invest in winches with documented maintenance histories and proper installations.

- 9. Environmental Impact: Hydraulic winches that are well-maintained are less likely to develop leaks or issues that could lead to environmental contamination. Responsible maintenance practices contribute to a reduced environmental impact.

In summary, proper installation and maintenance of hydraulic winches are integral to safety, reliability, and cost-effectiveness. These practices not only ensure the equipment’s longevity and performance but also contribute to safer working environments and compliance with industry regulations.

How do hydraulic winches compare to electric or manual winches in terms of performance?

Hydraulic winches, electric winches, and manual winches each offer distinct performance characteristics, and their suitability depends on the specific application. Here’s a comparison of hydraulic winches with electric and manual winches in terms of performance:

- 1. Load Capacity: Hydraulic winches typically outperform electric and manual winches in terms of load capacity. They can handle much heavier loads due to the hydraulic system’s ability to generate high force.

- 2. Line Speed: Electric winches tend to have faster line speeds compared to hydraulic winches, making them suitable for tasks that require quick retrieval or lifting. Hydraulic winches offer more precise control but may have slightly slower line speeds.

- 3. Precision and Control: Hydraulic winches offer precise control over load movement, making them suitable for applications that require accurate positioning or controlled lifting. Electric winches also provide good control, while manual winches may be less precise.

- 4. Continuous Operation: Hydraulic winches are well-suited for continuous operation without overheating. Electric winches can operate continuously, but some may require intermittent use to prevent overheating. Manual winches are generally used for intermittent or occasional tasks.

- 5. Versatility: Hydraulic winches are versatile and can handle a wide range of applications and load sizes. Electric winches are also versatile but may have limitations on load capacity and duty cycle. Manual winches are less versatile and typically used for lighter loads and simpler tasks.

- 6. Maintenance: Hydraulic winches may require more maintenance due to their hydraulic system, including fluid changes and hydraulic component checks. Electric winches have fewer maintenance requirements, while manual winches are relatively low maintenance.

- 7. Power Source: Hydraulic winches require a hydraulic power source, which can be an advantage or limitation depending on the availability of hydraulic systems in the application. Electric winches need electrical power, while manual winches rely on human effort.

- 8. Environmental Considerations: Hydraulic winches are suitable for a wide range of environments, including harsh conditions, but require hydraulic fluid. Electric winches may be limited by electrical connections, and manual winches are suitable for less demanding environments.

- 9. Cost: Hydraulic winches are often more expensive upfront due to their hydraulic system. Electric winches come in various price ranges depending on capacity and features, while manual winches are generally the most affordable option.

Ultimately, the choice between hydraulic, electric, or manual winches depends on the specific requirements of the application. Hydraulic winches excel in heavy-duty applications where high load capacity and precise control are essential. Electric winches offer a balance between versatility and speed, while manual winches are suitable for lighter tasks and situations where a power source is not available.

How does the hydraulic system contribute to the operation and power of hydraulic winches?

The hydraulic system plays a fundamental role in the operation and power of hydraulic winches. It provides the necessary force and control to perform winching tasks effectively. Here’s how the hydraulic system contributes to hydraulic winch operation:

- 1. Power Source: The hydraulic system of a hydraulic winch is typically powered by an external source, such as a hydraulic pump connected to an engine or a hydraulic power unit (HPU). This source generates hydraulic pressure, which is transmitted to the winch.

- 2. Hydraulic Fluid: Hydraulic fluid, usually hydraulic oil, is the medium that transmits power within the hydraulic system. When pressurized, the hydraulic fluid transfers force to the winch’s hydraulic motor, creating motion.

- 3. Hydraulic Motor: The hydraulic motor is a key component of the hydraulic winch. It converts the hydraulic pressure from the fluid into mechanical rotation. This rotation powers the winch drum, which winds or unwinds the cable or rope.

- 4. Control Valves: Control valves within the hydraulic system regulate the flow of hydraulic fluid to the hydraulic motor. These valves enable precise control over the winch’s speed, direction, and force. Operators can adjust these parameters as needed for the specific winching task.

- 5. High Torque Output: Hydraulic winches are known for their high torque output, which makes them capable of handling heavy loads. The hydraulic system’s ability to generate and control high pressure contributes to this torque, enabling the winch to exert substantial pulling or lifting force.

- 6. Continuous Operation: Hydraulic winches can operate continuously without overheating. The hydraulic system’s design ensures efficient heat dissipation, allowing for prolonged operation without the need for cooldown periods. This is crucial for tasks that require sustained winching.

- 7. Adaptability to Varied Loads: The hydraulic system’s pressure can be adjusted to suit different load requirements. This adaptability makes hydraulic winches versatile, capable of handling a wide range of loads with precision.

- 8. Reliability in Harsh Environments: Hydraulic systems are known for their durability and reliability in harsh environments. They are less susceptible to damage from factors like dust, moisture, and temperature extremes compared to electrical systems.

In summary, the hydraulic system provides the power, control, and reliability that hydraulic winches require for their operation. It enables these winches to exert high torque, adapt to various loads, offer precise control, and operate continuously, making them essential tools for heavy-duty winching tasks in diverse industries.

editor by CX 2023-12-12